English

T: +86-180-0799-3137

E: info@refinecolor.com

E: info@refinecolor.com

9F, Building 25, Tian 'an Shenchuanggu, Fenggang Town, Dongguan 523703, China

Views: 0 Author: Site Editor Publish Time: 2025-10-22 Origin: Site

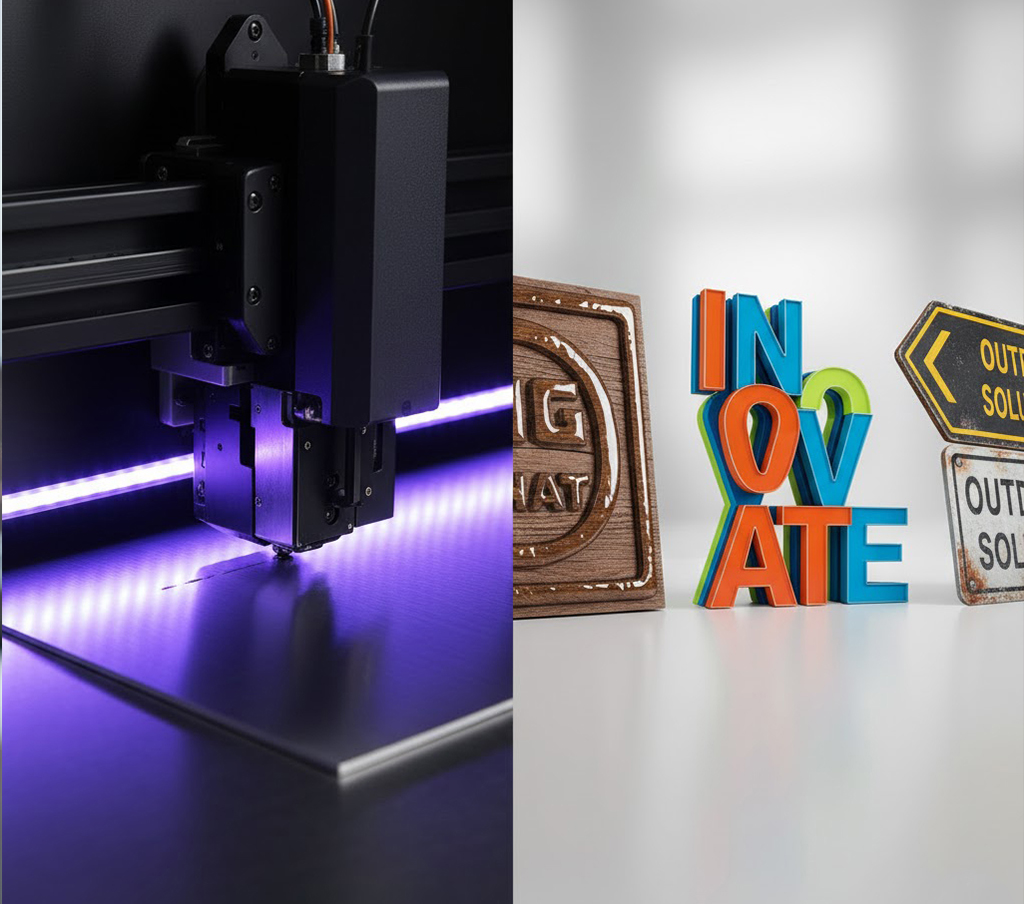

For signage distributors, production bottlenecks and material limitations are no longer a fixed cost of doing business. UV signage printer technology offers an alternative: securing your delivery timelines and profit margins by eliminating drying times, accepting a wider range of substrates, and making profitable, short-run custom jobs a daily reality.

In the traditional signage market, time is a liability. Your business is constrained by the limitations of outdated technology, forcing you to accept bottlenecks as a part of business.

The Wait-and-Waste Model: In solvent-based printing, delays are built into the process.1 You must account for extensive drying and off-gassing times. Every hour spent waiting is an hour you can't bill, which stifles your production capacity and delays cash flow.

The "Sorry, We Can't Print On That" Problem: Your business should be defined by its capabilities, not its limitations. Turning down high-value jobs for rigid substrates like acrylic, metal, or wood isn't a strategy—it's leaving money on the table. This constraint forces you to outsource or, worse, send clients directly to your competitors.

The Inherent Cost of Short Runs: Complex setups, especially for screen printing, are profit-killers on short runs.2 The high costs and labor involved eliminate your margins on custom, one-off jobs. Meanwhile, competitors using a UV printer for signage are capturing these high-profit, signage printer for custom designs projects with zero setup time.

The core of UV printer technology for signage printing is its 'print-and-cure' process, which eliminates the delays of older methods.3 It's a simple, four-step digital workflow:

Design Upload: The digital file (e.g., TIFF, PDF, EPS) is sent directly from the design station to the printer's RIP software.4

Precision Printing: The printhead deposits specialized UV inks for durable outdoor signage directly onto the substrate—whether it's metal, acrylic, vinyl, or wood.

Instant Curing: A high-intensity UV LED light system, integrated into the print carriage, cures (solidifies) the ink the instant it's applied.5 This molecular-level bond is the key to durable UV printing on signs.

Finished Product: The result is a vibrant, scratch-resistant, and weather-proof sign, ready for immediate delivery, lamination, or installation. There is zero drying time.

A printer sitting idle doesn't make you money. We engineer our systems for industrial uptime, focusing on the components that protect your investment and ensure consistent quality.

Industrial-Grade UV Curing: This isn't just about speed; it's about bond strength. Our powerful UV LED curing system ensures deep, thorough curing across the entire print. This process prevents the peeling, cracking, and fading common in outdoor applications, resulting in fewer customer complaints and virtually no rework.

Precision Engineering (The Non-Negotiables): We integrate industry-leading Honsonsoft mainboards and precision Servo-Driven systems. Why? Because misaligned prints, banding, and artifacts are unacceptable in the professional signage world. This architecture guarantees your 100th print is mechanically and visually identical to the first.

Ink Management is Risk Management: Our system features an automated White Ink Circulation and Stirring mechanism. This is not a minor feature; it is critical. It actively prevents the pigment from settling, which is the #1 cause of printhead clogs. Clogged heads mean downtime, costly repairs, and wasted ink. We designed this to protect your investment and ensure your printer is ready when you are.

Expand your service offerings beyond basic banners and into specialized, high-value applications that are impractical with analogue methods.

Braille Signage

UV printer for printing on outdoor signage

UV signage printing for exihibition

The Premium Application (ADA/Braille Signage): This is far more than flat printing; it's building textured, tactile layers. Using a signage printer for custom designs, you can create high-value, legally-required ADA signage. This is a low-competition market with high margins, and we provide the full "how-to" for your team.

The Versatility Play (Interior Décor & Wayfinding): Print directly on finished wood, brushed metal, and glass for high-end corporate offices, hotels, and retail spaces. This technology allows you to pivot from being a "sign guy" to a "custom décor partner," locking in high-value B2B contracts for UV printing on acrylic signs.

The Speed-to-Market Win (Trade Show & Event Graphics): Deliver custom, high-impact rigid displays and event graphics overnight. While your competitors are still waiting for solvent prints to dry and off-gas, you are delivering the finished job and getting paid. This agility becomes your single greatest competitive advantage.

Don't just take our word for it. Here is the reality of UV profitability from shops that have made the switch.

Common misconception: UV printers come with high costs..

Reality: Eliminating setup costs (screens, molds) and minimum order quantities means you can profitably accept $50 custom jobs, making it a perfect UV printer for promotional signage and one-offs.6 The ROI is calculated in months, not years. For most of our clients, we see a full return on investment within 6 to 18 months, depending on operational efficiency

[Case 1 ]: "Our RF-6090 paid for itself in 6 months just on short-run acrylic jobs." – Distributor, Germany.

Common misconception: Digital prints fade outdoors.

Reality: This is a holdover from older ink technologies. Our UV inks are engineered for 3-5 years of outdoor use without lamination. They are the ideal solution for a UV signage printer for outdoor signs and durable UV printing on metal signage.

[Case 2]: "We replaced our failing solvent-printed real estate signs. Our UV-printed signs have survived two Midwest winters without fading." – Sign Shop, USA.

Common misconception: UV printers are slow and inefficient for production.

Reality: Our high-resolution signage printing machine offers true on-demand printing with zero setup or drying time, enabling rapid turnaround on any job size. This workflow is fundamentally more efficient for a modern, high-mix sign shop.

[Case 3]: "Our UV printer for signage lets us fulfill same-day orders for custom signage, cutting our delivery time in half compared to traditional printing methods." – Print Shop, UK.

We offer a range of solutions scaled to your production needs.

Model | Print Size | Best For | Key Features |

RF-6090 UV Printer | 600×900mm | Your primary money-maker. Designed for daily production of storefront signs, metal plates, and rigid displays. The perfect balance of size and speed. | High-speed, multi-material support, Dual-head industrial-grade speed |

RF-A3+ UV Printer | 329×483mm | Perfect for print shops adding new UV services. Start with high-margin small items (promotional goods, awards, custom acrylics) with a low initial investment. | Compact, cost-effective, quick setup |

A: This is a critical point. Adherence is 90% preparation. For non-porous substrates like glass and polished metal, we recommend a primer/coating wipe. It's one simple extra step that guarantees a scratch-proof, permanent bond. We provide the full SOP (Standard Operating Procedure) and source for tested primers to ensure your success with UV printing on metal signage.

A: The two primary consumables are ink and printheads. Ink cost is low on a per-sign basis, often pennies per square foot, allowing for high margins. Printhead longevity is the most critical factor. Our systems protect this investment with white ink circulation to prevent clogs and a cap-top station to maintain head health, maximizing lifespan and minimizing costly replacements.

A: Absolutely. Traditional printing requires expensive setup (screens, plates) and minimum orders, making small jobs unprofitable. A UV printer for printing on vinyl or rigid boards has zero setup time, making it highly cost-effective for small businesses, custom shops, and anyone needing to produce one-off or short-run jobs profitably.

Send us your most difficult material—be it brushed aluminum, acrylic, or glass. We will print your design on it and ship it back to you. See the quality, test the adhesion, and prove the concept for yourself. Let us be your strategic partner in building a more profitable, versatile, and reliable signage business.

About Refinecolor Technology Co., Ltd: Based in Shenzhen since 2008, we deliver certified UV and inkjet printing solutions for different material, helping creators worldwide bring their ideas to life.

1 machine for printing mugs , 2 Profit Modes, N-Times the Profit

UV Metal Printing Machine: Turn Blank Metal into High-Margin Products

High-Resolution Acrylic Printer for Custom Designs And Artwork

Stop Losing Profit to Old Decal Methods — Switch to a UV Ceramic Decal Printer

UV leather printer: Stop the price war and start selling "touch" and "unique value”

Glass Printing Machine: The Best Solution for Custom Glass Printing

How To Make An Embossed Image on Acrylic with Refinecolor UV Printer