English

T: +86-180-0799-3137

E: info@refinecolor.com

E: info@refinecolor.com

9F, Building 25, Tian 'an Shenchuanggu, Fenggang Town, Dongguan 523703, China

Views: 0 Author: Site Editor Publish Time: 2025-10-22 Origin: Site

This Article written by the RefineColor Engineering Team

With over 20 years of industrial printing experience, we specialize in innovative printing technologies designed to drive efficiency and maximize profit for businesses

Stop Outsourcing. Control Your Quality, Cut Costs with UV printing for metal surfaces, and Capture the $XX Billion Custom Metal Market. Built for Reliability, Priced for Profit

In the custom printing market, "no" is the most expensive word. How many custom orders under 50 pieces did you reject last month? Does the non-refundable plate-making fee for silk-screen printing make your short-order quotes completely uncompetitive? When a client wants a five-color logo with a gloss finish, can your laser engraver do anything but burn a single-color design?

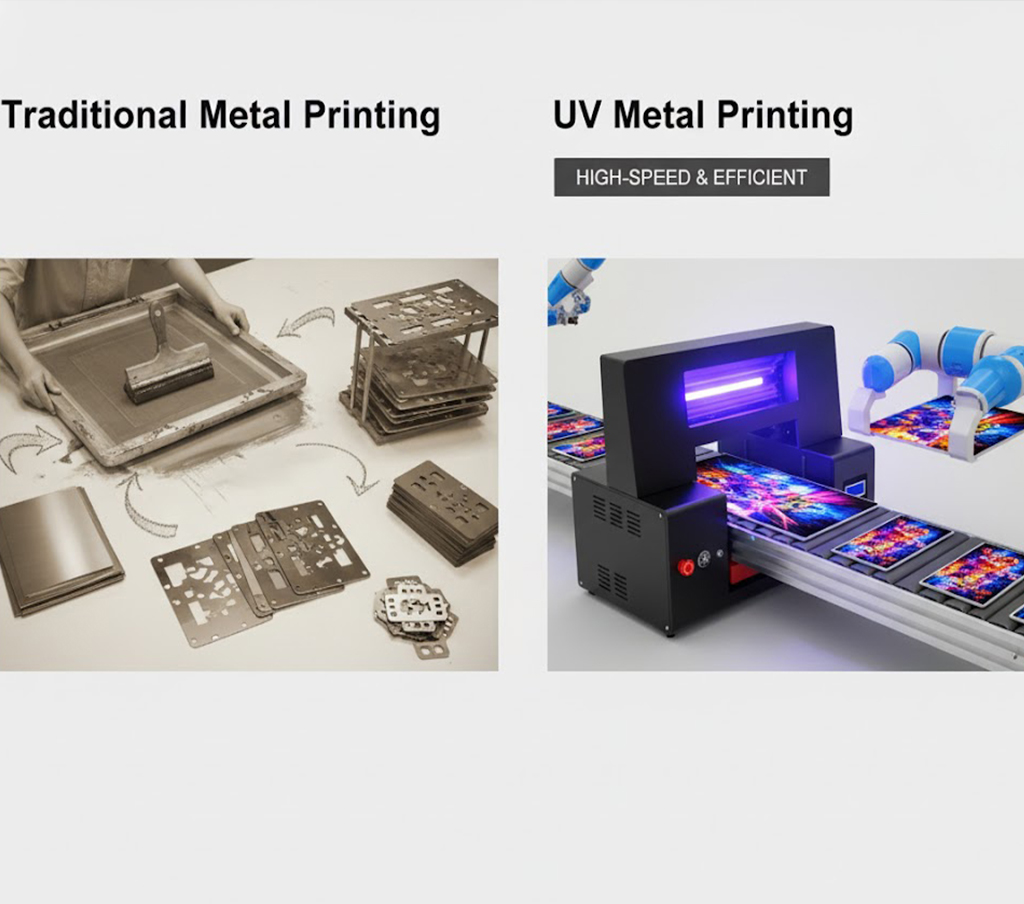

Traditional metal printing was built for mass production, creating barriers of slow setup, high costs, and crippling color limitations. This is where your profit margins leak and where your customers turn to competitors.

UV metal printing technology revolutionizes this equation. It's not just an equipment upgrade; it's a business model transformation. Imagine zero plate-making fees. A minimum order quantity (MOQ) of one. The ability to print full color (CMYK), opaque white, and tactile varnish effects in a single, automated pass. With a UV metal printing machine, the only barrier to accepting an order is the time it takes you to press "print."

Understanding how does a UV metal printing machine work reveals its value. The process is a precise, three-stage system that delivers industrial-grade results.

Let’s be honest: “Coating-free” printing has unreliable adhesion to dense, non-porous surfaces like polished stainless steel or smooth aluminum. Our solution is a proprietary metal coating/primer. This isn't just a suggestion; it's our professional process for guaranteeing results. With just a light wipe before printing, our UV ink "bites" into the metal surface, achieving industrial-grade scratch and weather resistance that "coating-free" methods can't match.

After prepping the metal, the printer's piezoelectric printheads get to work. With precise control, they jet tiny droplets of UV-curable ink in a specific pattern. Let me give you a real-world example:

When printing on a dark metal surface like brushed aluminum, the first step is to apply an opaque white base (White Ink, W). This is essential because the white layer acts as a color amplifier, making the final print pop. I've had customers struggle with this in the past, where without this step, their designs looked faded and washed out on dark metals. It's not just about color, but about achieving the vibrancy that customers expect.

Next, the full-color image (CMYK) is applied directly over this base. Imagine a vivid logo on a dark surface—this layering method allows the colors to come through clear and true, as if printed on a white canvas.

Finally, a Varnish layer is added for durability and extra flair. For high-end items like corporate awards or premium signage, we often apply varnish to specific areas to give it a 3D feel. A client once asked for a "luxury" finish on a custom metal plaque, and after applying this varnish technique, they were thrilled with the premium tactile effect that made the logo literally "shine" from the matte background. It's the little details that make all the difference in high-end markets.

This is what is UV printing on metal surfaces all about. Attached to the print carriage, a high-intensity, cool-running UV LED lamp passes over the wet ink. The UV light instantly polymerizes (cures) the ink, turning it from a liquid to a solid, durable layer. There is no drying time. The printed metal part is 100% cured and ready for handling or shipping the moment it leaves the printer. The UV ink forms a permanent, durable bond, offering superior scratch, chemical, and weather resistance.

Based on tests conducted on 304 stainless steel panels (100×150 mm) with Xenon lamp exposure — color fading ΔE < 1.5 after 300 hours

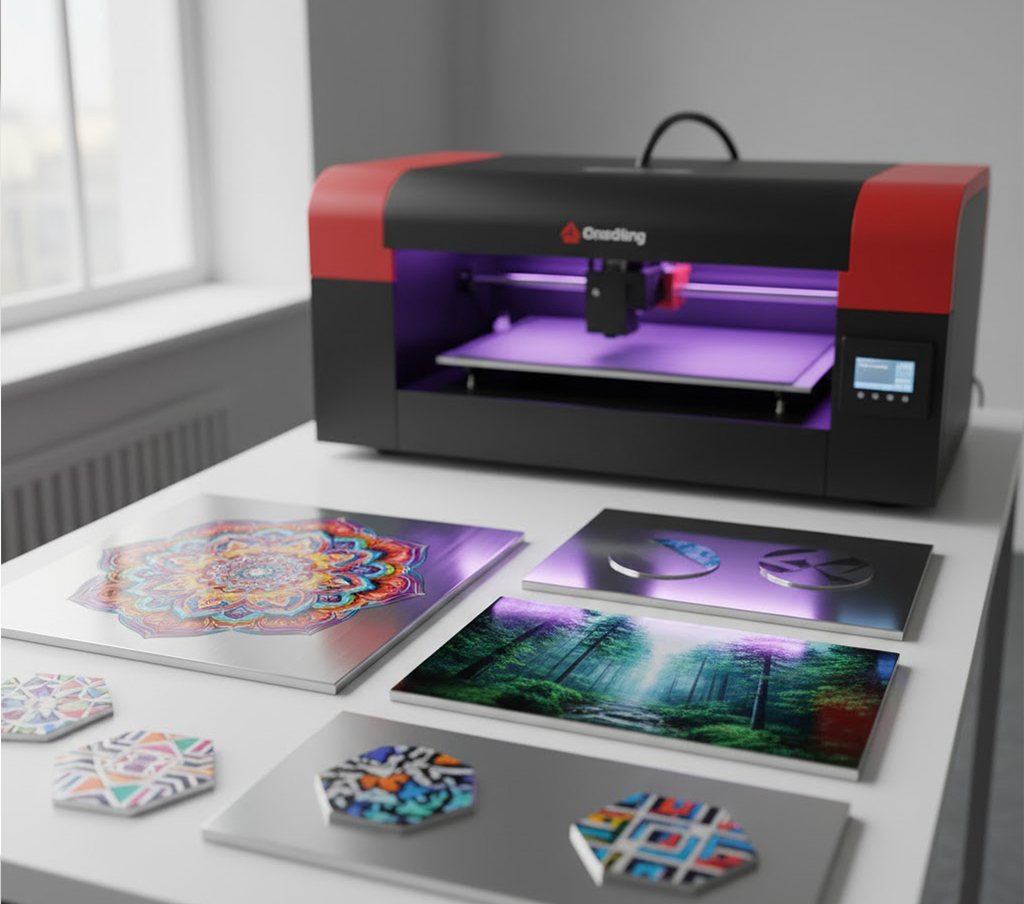

The fastest path to profit is to stop selling "printing services" and start selling finished, high-value products. A UV metal printer for custom designs opens doors to multiple lucrative verticals.

UV metal printer for custom metal signage

UV printer for printing on aluminum and steel

UV printer for metal labels and tags

metal printing machine for promotional products

UV printing on metal parts for automotive

Application Category | Example Use Cases |

UV metal printer for custom Signage & Branding | Custom aluminum office signs, brushed metal lobby logos, wayfinding plaques. |

UV printer for printing on Automotive metal& Industrial | Printing logos on custom parts, serial numbers on components, control panel faceplates. |

UV printer for metal labels&tags | Durable, full-color metal asset tags, warning labels, industrial product branding. |

UV printing on metal for corporate gifts | Full-color logos on metal water bottles, USB drives, and corporate awards. |

UV printer for art on metal surfaces& Décor | Printing high-resolution photography or custom artwork on brushed metal sheets. |

While the initial cost of the machine might seem like the biggest expense, the real value comes from how quickly it starts paying you back. As you incorporate UV metal printing into your daily operations, you’ll notice that your return on investment is driven by the savings on setup time, material costs, and the new profit opportunities that open up with custom orders

With traditional printing, creating a single sample or a small is a money-losing proposition. But with a UV flatbed printer for metal, your margins change completely. I’ve seen workshops reduce their setup costs significantly—print a one-off sample, and it costs almost the same as printing a hundred pieces. This allows you to offer clients "free proofs" without the fear of losing money, turning it into a competitive sales advantage. We’ve had a client in custom signage use this approach to convert leads into sales faster than ever before, giving them a huge edge over competitors who charge hefty setup fees

Don't just sell flat color prints. Our machines support multi-layer "varnish" printing. This is your hidden margin multiplier. This feature allows you to offer premium, high-touch effects like "3D embossing" (where a logo is physically raised), "local gloss" (making a logo shine on a matte background), or "premium matte." This value-added service requires no extra equipment and minimal ink, turning a $2 sign into a $10 premium product. It's pure profit margin improvement.

This isn't a sticker. UV ink adhesion on metal surfaces is industrial-strength . Do not just tell your customers it's durable; show them. We encourage you to create sales videos: scrape a print with a key, wipe it with an alcohol-soaked cloth, leave it outdoors. Demonstrating this resilience builds immense trust and justifies a premium price point, positioning your products far above hobbyist-grade solutions.

l Personalized Metal Business Cards: A boutique consulting firm wants 100 brushed-black metal business cards. Laser engraving is too basic. You print their full-color logo, add an opaque white layer for vibrancy, and use varnish to give their logo a raised, 3D texture. You've created a high-end, tactile product that commands a premium price.

l Metal Medals and Trophies: A local marathon needs 300 finisher medals, each with the event logo, date, and a "Top 10" designation for specific pieces. Using a jig, you print directly onto the blank medals, handling the full-color logo and variable data text in a single run.

l Souvenirs and Gifts: A corporation orders 500 commemorative coins for its 25th anniversary. You print the company's complex, multi-color logo directly onto the metal blanks, delivering a high-perceived-value gift that screen printing could never achieve at that volume. That's why the UV printing on metal for branding is most profitable

This technology is not just for print shops; it's a powerful tool for manufacturers looking to integrate customization.

High-Speed Prototyping & Production: A high-resolution UV printer for metal bridges the gap between R&D and manufacturing. A new design for a control panel can be designed, printed, and tested in under an hour, allowing for rapid iteration without costly re-tooling.

Low Setup Costs for High-Mix Runs: For manufacturers producing many different product SKUs, UV printing is the ultimate solution. "Re-tooling" for a new design is as simple as opening a new digital file. This makes high-mix, low-volume production highly profitable.

Built for the "Factory Floor": Our machines aren't fragile "office" equipment. They are designed for long-term, continuous operation. They utilize a reinforced all-steel body, precision dual linear guide rails, and imported Japanese servo motors to ensure 24/7 operational stability. Less downtime isn't just a feature; it's your business continuity.

A: Almost all. It works perfectly on common metals like aluminum, brushed stainless steel, tin, and brass. For extremely smooth, slick surfaces like glass or highly polished chrome, we strongly recommend using our adhesion primer to ensure permanent, industrial-grade adhesion. We provide a complete substrate-to-process guide so you never have to guess.

A: When paired with our primer, the prints are exceptionally durable. They are highly resistant to scratches, abrasion, chemicals (like alcohol or cleaning solvents), and fading from UV exposure. For outdoor applications, they can last 3-5+ years without lamination.

A: This is the biggest operational challenge for all UV printers, regardless of brand, especially with white ink. We address this directly. Our machines integrate an automatic white ink circulation and stirring system, automatic printhead cleaning cycles, and a negative pressure ink supply to minimize this risk. We provide a simple "5-minute daily maintenance process." As long as you follow this simple procedure, your machine will remain in optimal, ready-to-print condition. We provide a partnership, not just a machine.

A: Yes, compared to traditional solvent-based printing, it is significantly better. Our UV inks are low in Volatile Organic Compounds (VOCs). The UV LED curing process is energy-efficient and produces no ozone.

UV Metal Printing Machine: Turn Blank Metal into High-Margin Products

High-Resolution Acrylic Printer for Custom Designs And Artwork

Stop Losing Profit to Old Decal Methods — Switch to a UV Ceramic Decal Printer

UV leather printer: Stop the price war and start selling "touch" and "unique value”

Glass Printing Machine: The Best Solution for Custom Glass Printing

How To Make An Embossed Image on Acrylic with Refinecolor UV Printer