English

T: +86-180-0799-3137

E: info@refinecolor.com

E: info@refinecolor.com

9F, Building 25, Tian 'an Shenchuanggu, Fenggang Town, Dongguan 523703, China

| Availability: | |

|---|---|

| Quantity: | |

By choosing our uv printing machines, you are bypassing distributors and partnering directly with the factory. This direct relationship provides significant advantages

| |

|  |

| |

|  |

Engineered for precision and versatility, this A3+ ultraviolet printing machine is the definitive solution for businesses requiring high-fidelity, direct-to-substrate printing capabilities. As the direct manufacturer of this advanced uv print machine, we provide an industrial-grade platform built for reliability, expanded application potential, and superior output quality. This system is designed not just to meet your current production demands but to unlock new revenue streams through innovative product customization.

Core Technical Selling Points

High-Fidelity 2880dpi ResolutionAchieve unparalleled precision for technical markings, intricate schematics, fine text, and photorealistic graphics. The dual Epson XP600 printheads, driven by a precision servo motor, ensure flawless edge-to-edge accuracy and repeatability on every run |  |

|

20cm Vertical Substrate ClearanceMove beyond flat media. Our robust, adjustable gantry supports direct printing on materials and objects up to 20cm (7.87 inches) thick, dramatically expanding your material selection from standard sheets to pre-assembled products and complex industrial components. |

6-Channel CMYKW+Gloss Ink SystemGo beyond standard 2D printing. Produce tactile, high-value finishes with our versatile ink configuration. Generate vibrant colors on dark or transparent substrates with a high-opacity white ink base, and apply targeted varnish to create stunning layered 3D embossed textures, high-gloss spot finishes, or sophisticated matte effects |  |

| Intelligent Production FeaturesThis uv machine for printing is equipped with an automatic media height detection sensor for rapid job setup and an anti-collision system to protect the printheads, ensuring streamlined, safe, and reliable operation across diverse and irregular materials |

| Printing Size | 33×60 cm(13×23.6 inch) | Print Head | On demand Epson XP600 Piezo electric printhead. Made-in-Japan. |

| Print Technology | UV led | Operating system | Windows PC |

| Printing Speed | 3minutes/A3 | Print size | 870×780×650 mm (34.3×30.7×25.6 inch) |

| Inks | UV Inks CMYK+White+Gloss | Shipping Size | 980×910×830mm (38.6×35.8×32.7 inch) |

| Application | Mobile phone cases, cards, stone sheet, Leather, wood, pens, golf-ball, bottles | Printer weight | 56KG |

| Print Model | 8pass/12pass/16pass | Shipping weight | 87KG |

| Printable Thickness | Up to 20cm(7.87inches) | Flatbed Transmission | Servo Motor |

| Resolution | Up to 2880×1440 dpi | Package including | USB line, power cable, user's manual book, spare parts , USB Driver, Keydog, extra dampers, Inks tunnel etc. |

| Interface | Network cable |

At the core of this uv printing machine is a commitment to uncompromised quality. The flatbed transmission is powered by a high-torque servo motor, eliminating the inconsistencies found in belt-driven systems and guaranteeing exceptional positional accuracy. Combined with the On-Demand Piezo electric printheads, this results in superior gradient smoothness and dot placement.

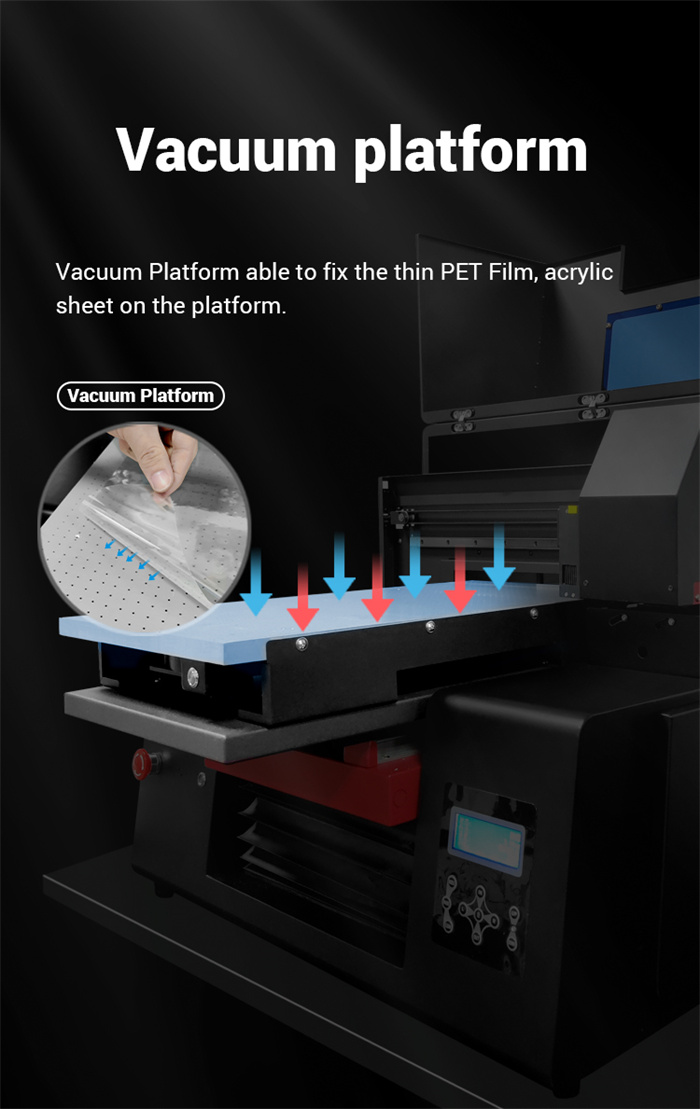

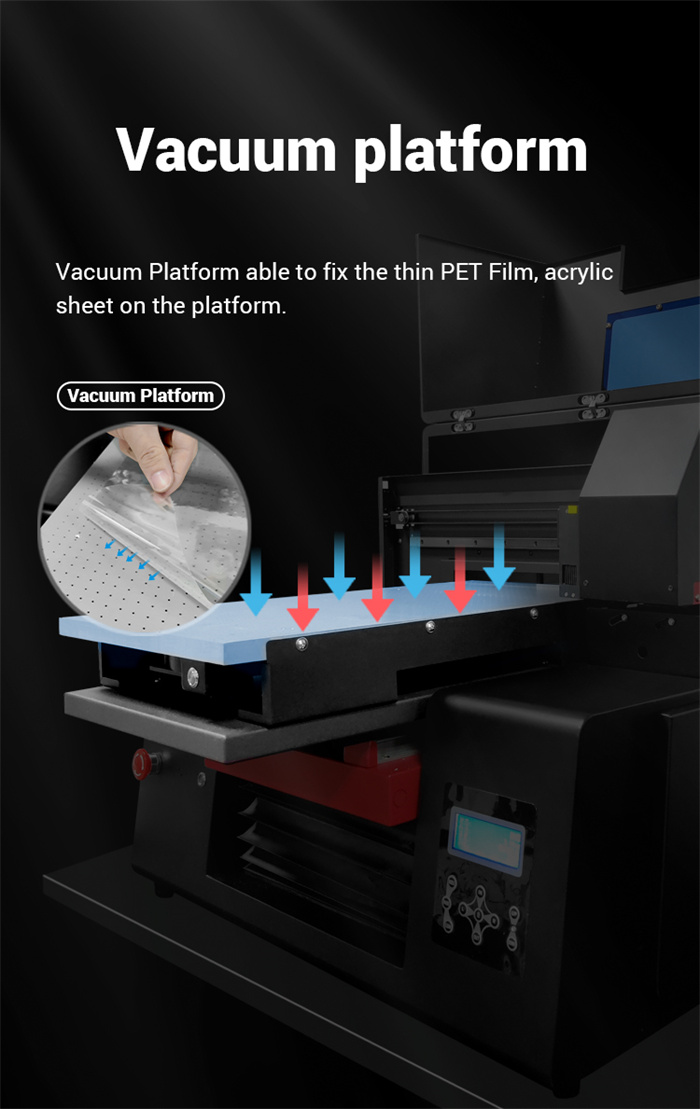

The integrated vacuum suction platform firmly secures media, preventing slippage and ensuring perfect registration for multi-layer jobs, which is critical for producing complex tactile effects.

Leverage a single, powerful platform to print on a virtually limitless range of rigid and flexible substrates. This machine is engineered to deliver outstanding adhesion and durability on materials including:Glass & Acrylic,Metals (Aluminum, Steel, Brass),Wood and MDF,Leather & PVC,Stone Sheeting & Ceramics,Promotional Items (Pens, Golf Balls),Cylindrical Objects (Bottles, Candles) via optional rotary jig.

Whether you are printing on PET film for irregular surface transfers (UV DTF) or printing directly onto finished goods, our system provides the operational flexibility your business requires.

Contact our engineering team today to discuss your specific application requirements, request a print sample, or receive a direct-from-factory quote for our premier uv printing machines. Let us demonstrate how our technology can integrate seamlessly into your workflow and enhance your product offerings.

Looking for more options? Explore our complete A3 UV Printer series or discover other printer types like 6090 UV Printers and UV DTF Printers.

By choosing our uv printing machines, you are bypassing distributors and partnering directly with the factory. This direct relationship provides significant advantages

| |

|  |

| |

|  |

Engineered for precision and versatility, this A3+ ultraviolet printing machine is the definitive solution for businesses requiring high-fidelity, direct-to-substrate printing capabilities. As the direct manufacturer of this advanced uv print machine, we provide an industrial-grade platform built for reliability, expanded application potential, and superior output quality. This system is designed not just to meet your current production demands but to unlock new revenue streams through innovative product customization.

Core Technical Selling Points

High-Fidelity 2880dpi ResolutionAchieve unparalleled precision for technical markings, intricate schematics, fine text, and photorealistic graphics. The dual Epson XP600 printheads, driven by a precision servo motor, ensure flawless edge-to-edge accuracy and repeatability on every run |  |

|

20cm Vertical Substrate ClearanceMove beyond flat media. Our robust, adjustable gantry supports direct printing on materials and objects up to 20cm (7.87 inches) thick, dramatically expanding your material selection from standard sheets to pre-assembled products and complex industrial components. |

6-Channel CMYKW+Gloss Ink SystemGo beyond standard 2D printing. Produce tactile, high-value finishes with our versatile ink configuration. Generate vibrant colors on dark or transparent substrates with a high-opacity white ink base, and apply targeted varnish to create stunning layered 3D embossed textures, high-gloss spot finishes, or sophisticated matte effects |  |

| Intelligent Production FeaturesThis uv machine for printing is equipped with an automatic media height detection sensor for rapid job setup and an anti-collision system to protect the printheads, ensuring streamlined, safe, and reliable operation across diverse and irregular materials |

| Printing Size | 33×60 cm(13×23.6 inch) | Print Head | On demand Epson XP600 Piezo electric printhead. Made-in-Japan. |

| Print Technology | UV led | Operating system | Windows PC |

| Printing Speed | 3minutes/A3 | Print size | 870×780×650 mm (34.3×30.7×25.6 inch) |

| Inks | UV Inks CMYK+White+Gloss | Shipping Size | 980×910×830mm (38.6×35.8×32.7 inch) |

| Application | Mobile phone cases, cards, stone sheet, Leather, wood, pens, golf-ball, bottles | Printer weight | 56KG |

| Print Model | 8pass/12pass/16pass | Shipping weight | 87KG |

| Printable Thickness | Up to 20cm(7.87inches) | Flatbed Transmission | Servo Motor |

| Resolution | Up to 2880×1440 dpi | Package including | USB line, power cable, user's manual book, spare parts , USB Driver, Keydog, extra dampers, Inks tunnel etc. |

| Interface | Network cable |

At the core of this uv printing machine is a commitment to uncompromised quality. The flatbed transmission is powered by a high-torque servo motor, eliminating the inconsistencies found in belt-driven systems and guaranteeing exceptional positional accuracy. Combined with the On-Demand Piezo electric printheads, this results in superior gradient smoothness and dot placement.

The integrated vacuum suction platform firmly secures media, preventing slippage and ensuring perfect registration for multi-layer jobs, which is critical for producing complex tactile effects.

Leverage a single, powerful platform to print on a virtually limitless range of rigid and flexible substrates. This machine is engineered to deliver outstanding adhesion and durability on materials including:Glass & Acrylic,Metals (Aluminum, Steel, Brass),Wood and MDF,Leather & PVC,Stone Sheeting & Ceramics,Promotional Items (Pens, Golf Balls),Cylindrical Objects (Bottles, Candles) via optional rotary jig.

Whether you are printing on PET film for irregular surface transfers (UV DTF) or printing directly onto finished goods, our system provides the operational flexibility your business requires.

Contact our engineering team today to discuss your specific application requirements, request a print sample, or receive a direct-from-factory quote for our premier uv printing machines. Let us demonstrate how our technology can integrate seamlessly into your workflow and enhance your product offerings.

Looking for more options? Explore our complete A3 UV Printer series or discover other printer types like 6090 UV Printers and UV DTF Printers.

UV leather printer: Stop the price war and start selling "touch" and "unique value”

Stop Losing Profit to Old Decal Methods — Switch to a UV Ceramic Decal Printer

High-Resolution Acrylic Printer for Custom Designs And Artwork

Glass Printing Machine: The Best Solution for Custom Glass Printing

How To Make An Embossed Image on Acrylic with Refinecolor UV Printer