English

T: +86-180-0799-3137

E: info@refinecolor.com

E: info@refinecolor.com

9F, Building 25, Tian 'an Shenchuanggu, Fenggang Town, Dongguan 523703, China

Views: 0 Author: Site Editor Publish Time: 2025-10-16 Origin: Site

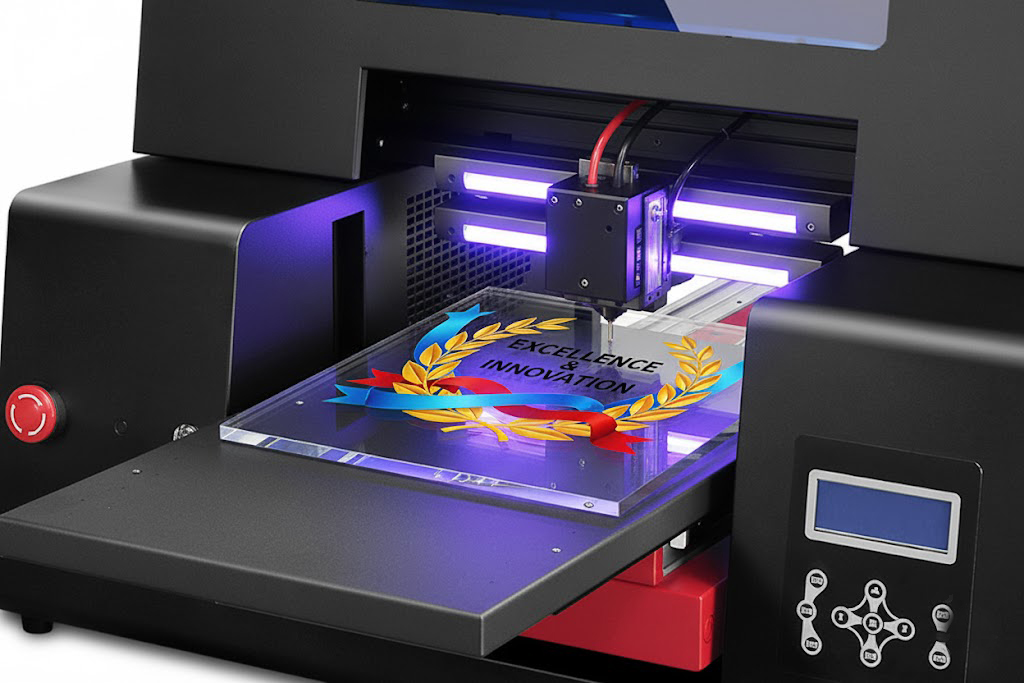

Transform Plain Glass into Premium, High-Value Products with Unmatched Precision and Durability. This is the future of custom decoration.

The demand for custom-decorated glass products is rapidly increasing across industries like beverages, corporate gifting, and interior design, as businesses strive for innovative, high-quality solutions. Traditional methods like screen printing or etching are often slow, costly for short runs, and limited in color complexity. The glass uv printing machine changes the entire equation. By utilizing advanced UV curing technology, these printers apply vibrant, durable, and intricate designs directly onto a vast range of glass surfaces, offering a powerful tool for businesses to innovate and grow.

Precise Printing and Detail:

UV printing technology is particularly well-suited to glass surfaces, enabling high-resolution, intricate images and designs. This is unmatched by traditional technologies like screen printing, especially when it comes to rendering fine details and small patterns. Glass's inherent smoothness demands high printing precision, but UV printing, through precise control of ink volume and printhead position, ensures that images appear delicately on glass.

Multi-layer Printing (such as white ink and varnish):

Glass products often require multiple layers of printing, especially for customized products. The use of white ink is crucial. White ink, as a base color, ensures color saturation and contrast, and is particularly effective on glass surfaces, especially transparent or light-colored glass. UV printers utilize a multi-channel ink system (CMYK + white + varnish) to create designs with relief, gloss, or gradient effects, giving glass products a more layered and premium look.

Instant Curing and Efficient Production:

Another key advantage of UV printing is its instant curing function, meaning printed images require virtually no drying time. For glass products, UV curing technology can quickly harden the ink, avoiding the problem of ink fluidity and ensuring the stability of the pattern and durability after printing.

Selecting the right partner and technology is critical to your success. Our glass printer solutions are engineered to provide a distinct competitive advantage, enabling you to deliver what your clients demand: uncompromising quality, speed, and versatility.

Photorealistic Precision: With the advanced Epson XP600 printhead, our machines deliver a stunning resolution of up to 2880 DPI, ensuring that even the most intricate logos, detailed images, and sharp text are flawlessly reproduced on glass surfaces

Exceptional Durability: The unique UV inks we use are instantly cured by a high-efficiency UV LED system, creating a strong bond with the glass surface. The result is a finish that resists scratches, moisture, and fading, making it perfect for both functional and decorative pieces.

Unmatched Versatility: Print on flat glass sheets, awards, and even cylindrical objects like bottles and drinkware up to 20 cm in height. Our UV printer for glass handles a wide array of products, opening up multiple revenue streams with a single machine.

Advanced Color Capability: The White + CMYK + Varnish ink system allows for printing vibrant, opaque colors on transparent or dark glass, as well as creating stunning 3D embossed and high-gloss varnish effects.

Full-Color Vibrancy: By first printing a base layer of high-opacity white ink, our printer ensures that CMYK colors appear brilliant and true-to-life, even on transparent glass.

Elegant White Ink Printing: Use white ink as a standalone color for sophisticated, high-contrast designs on clear or colored glass.

Premium Varnish & Embossed Effects: Apply a clear varnish layer for a glossy, protective finish or build it up to create tangible, 3D-embossed textures that customers can see and feel.

Our glass printers feature a streamlined, efficient workflow that simplifies production. By understanding this process, your customers will see just how easy and valuable it is to operate.

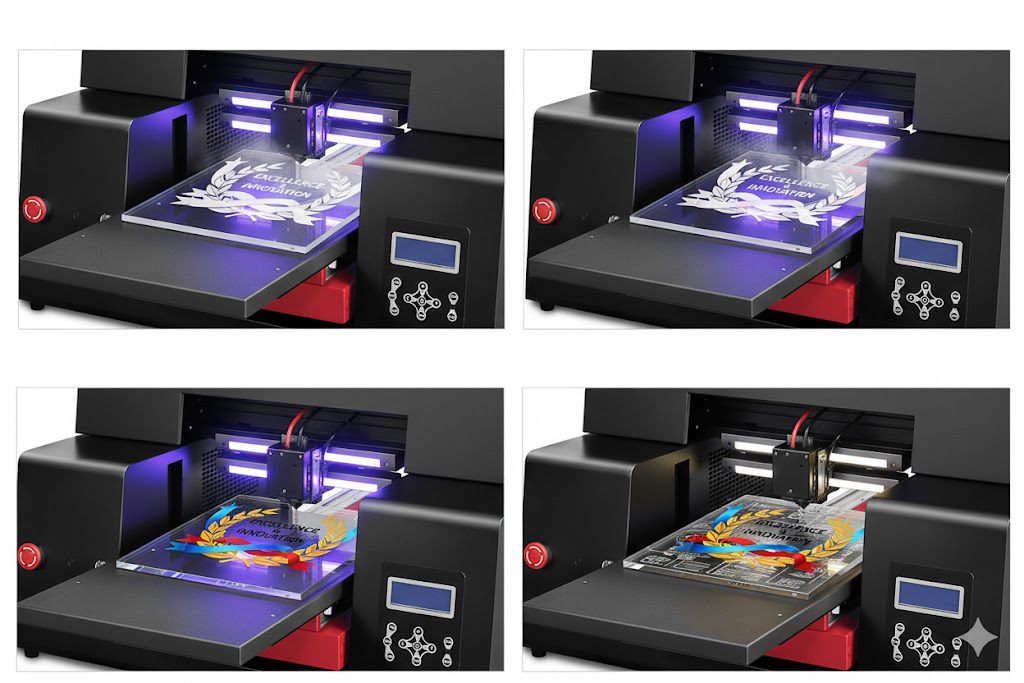

1.Surface Preparation: The glass item is cleaned to ensure it is free of dust and oils for optimal ink adhesion.

2.Secure Placement: The product is placed on the printer's flatbed. An automatic height detection sensor precisely calibrates the distance between the printhead and the glass surface, guaranteeing sharp, consistent results every time.

3.Design to Print: The digital design is sent from the intuitive RIPRINT software to the printer. This powerful software allows for complete control over color, layout, and ink layering (white, color, and varnish).

4.Instant Curing & Printing: The UV glass printer meticulously applies the ink layers. Simultaneously, the built-in UV LED lamps cure the ink instantly, ensuring the product is completely dry and ready for handling or shipping immediately after printing.

Choosing the right equipment depends on your specific production needs and target applications. Here are key factors to consider:

Object & Material Type: Do you need to print on bottles, trophies, or flat sheets? Ensure your chosen machine, like our Refinecolor RF-ZZ1C, has the necessary height clearance and robust build to handle diverse product shapes and weights.

Precision & Color Quality: For high-end applications, resolution and color capabilities are paramount. A machine with dedicated white ink and varnish channels is essential for producing premium, multi-textured effects that command higher prices.

Printing Scale & Size: Assess the maximum size of the glass products you intend to print. Our A3+ (33x60cm)RF-ZZ1C format is a multi-function solution, design for everything from small glassware to larger decorative panels.And we also have more big size RF-6090GY which support 33x60cm,you can compare it as the following

our glass UV printing machine empowers you to serve a wide range of industries.

High-end alcoholic beverage packaging

Glass bottles hold a significant position in high-end alcoholic beverages, particularly wine, spirits, and premium beer. More and more brands are turning to customized packaging to add value and enhance their brand image. UV printers can print exquisite brand logos, graphic designs, and labels on glass bottles, enhancing the packaging's visual appeal and brand recognition.

Our UV printers are capable of printing on a range of glass types, including standard, tempered, frosted and coated varieties - offering consistent adhesion results across both flat surfaces and cylindrical objects with ease.

Each UV printer comes equipped with an automated printhead cleaning and ink circulation system to facilitate maintenance. Simply following basic daily and weekly procedures will help ensure consistent performance and longevity.

UV-cured ink is highly durable and resistant to abrasion, chemicals and moisture exposure - ideal for functional items like drinkware as well as decorative pieces with appropriate care taken.

While pricing varies based on model and configuration, our solutions have been tailored to provide rapid returns on investment through producing customized high-margin products efficiently. Contact our team for a personalized quote that aligns with your business goals.

Case Study: The Corporate Awards Supplier A long-established supplier specializing in corporate awards and recognition products faced increasing competition from suppliers offering similar items at cheaper prices. To stand out and attract high-value corporate clients, they integrated an RF-ZZ1C UV Printer as part of their strategy for offering fully customized glass trophies. First major order for this company came from a high-profile tech firm who needed custom designed trophies with full color printing capability using White+CMYK+Varnish ink systems from Roland Fanz RF-ZZ1C printers - perfectly capable of reproducing intricate company logos, intricate designs and embossed text on precision! A3+ printing size enabled them to accommodate large custom logos while the Epson XP600 printhead guaranteed resolution of up to 2880 DPI for visually stunning trophies. Quick turnaround time and an automated printhead cleaning system ensured the company could meet stringent deadlines, further drawing in corporate clients with demanding schedules. This new ability to offer high-quality, fully customizable awards with embossed 3D effects set them apart from their competition and led them to see a 50% surge in corporate clients within six months. Utilizing the RF-ZZ1C, they not only improved profitability but also cemented themselves as industry leaders for premium, personalized awards.

content is empty!

content is empty!