English

T: +86-180-0799-3137

E: info@refinecolor.com

E: info@refinecolor.com

9F, Building 25, Tian 'an Shenchuanggu, Fenggang Town, Dongguan 523703, China

| Availability: | |

|---|---|

| Quantity: | |

The cylindrical printing industry has long been stuck with three critical pain points: focus deviation on tapered objects, dull colors on dark substrates, and seamless joint gaps on large-diameter workpieces. Most devices are either "patched solutions" of flatbed printers plus rotary attachments or sacrifice resolution for speed. Our 360 Rotary UV Printer is an integrated system specifically engineered to solve these "industry chronicles"—and it’s the tangible embodiment of our original "Cylindrical Printing 4.0" concept (Precision Synchronization + Instant Curing + Universal Substrate Compatibility). It’s not just about "being able to print"; it’s about elevating cylindrical/curved surface printing from "barely usable" to "high-efficiency and precision" fully adapting to the mass customization production demands.

Our Printer offers high precision in printing on cylindrical and conical surfaces.It's engineered to solve the most significant challenge in cylindrical printing: maintaining high resolution and adhesion without distortion, even during a full 360-degree wrap.

Whether you're printing on tumblers, water bottles, glassware, or custom industrial components, this cylinder uv printer delivers high-resolution, vibrant prints with instant curing. The integrated uv printer with rotary attachment ensures perfect synchronization between the printhead and the item's rotation, resulting in seamless, edge-to-edge graphics that flatbed printers simply cannot achieve.

We move beyond basic specifications to focus on features that deliver real-world profitability. This machine is built for operators who demand reliability and quality.

Most cylindrical printers on the market compress resolution to 1440 DPI for speed, resulting in jagged edges on brand logos or intricate patterns within 1mm. We insist on a maximum output of 2880 DPI, paired with our exclusive "micro-droplet precision control technology." Even English initials on tumblers or gradient textures on cosmetic bottles maintain "sharp clarity when magnified 3x." This is critical for high-end customization and corporate gifts that demand "brand texture," directly reducing return rates caused by printing flaws.

Ordinary "flatbed + rotary attachment" devices suffer from unsynchronized movement between the printhead and workpiece rotation, often leading to "1mm overlap at the start and end" or "blank gaps in the middle." Our machine adopts "dual-axis synchronous drive technology"—the printhead movement speed is real-time calibrated with the workpiece's rotational angular velocity, controlling errors within 0.01mm. Whether it’s industrial pipes with a diameter of 600mm or small water cups of 100mm, it achieves "one-time molding without splicing." This is especially ideal for promotional products and packaging bottles that require full-wrap designs.

Dark metals and transparent glass have long been "color rendering nightmares" for cylindrical printing—ordinary devices either produce dull colors or suffer from poor adhesion (peeling with a touch). Our solution features an exclusive "two-step curing logic": first, a high-opacity white ink is sprayed to form an "optical base layer," instantly cured by UV light to lock it in place; then the CMYK color layer is applied, with a second curing to enhance adhesion. The result? "Vibrant, non-fading colors"—a red logo on a black tumbler stays bright, and patterns on transparent wine glasses resist wear and washing. This solves the industry pain point of "material limitations restricting design possibilities."

This printer is not only a uv rotary printer for tumblers, but also its capabilities extend far beyond that.Its adjustable system and advanced ink chemistry allow you to print directly on a vast range of substrates, including:

Glass

Stainless Steel

Coated Metals

Hard Plastics (Acrylic, PVC)

Wood (bamboo cups)

Ceramics

The cylindrical uv printer is designed for high-volume, quick-turnaround production.Its stable build, reliable components, and intuitive workflow software reduce setup time, minimize waste, and allow your business to confidently accept large and complex orders. The right features can significantly impact the long-term 360 rotary uv printer price and ownership cost, making this an intelligent investment.

This uv cylinder printer opens new markets and revenue streams. Its versatility makes it the ideal solution for multiple industries.

Custom Tumblers: Print custom designs on tumblers and drinkware with high precision and vibrant colors.

Custom Mugs: Print full-color, detailed images on ceramic mugs, coffee cups, and other cylindrical objects.

Glassware & Bottles: Ideal for printing logos, images, and text on glass bottles, wine glasses, and promotional items.

Personalized perfume bottle design: Providing perfume brands or high-end custom brands with personalized patterns and customized bottle printing (such as brand logos, limited edition patterns, etc.) for perfume bottles.

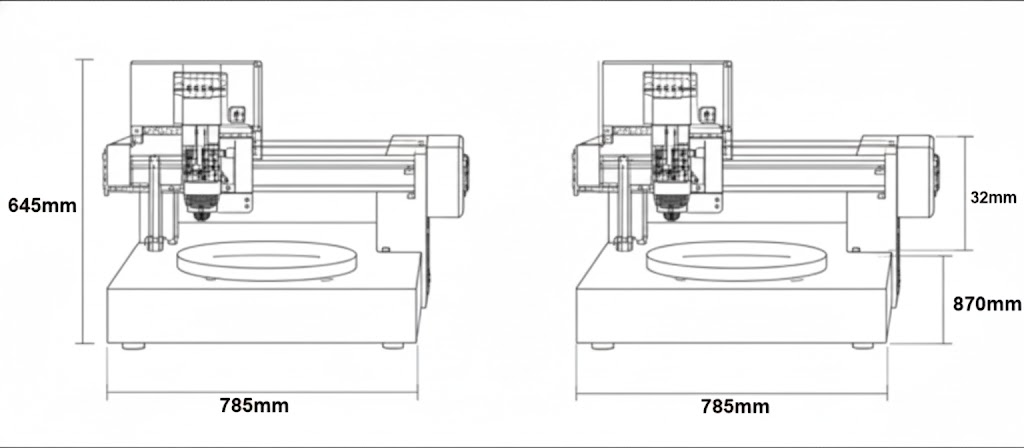

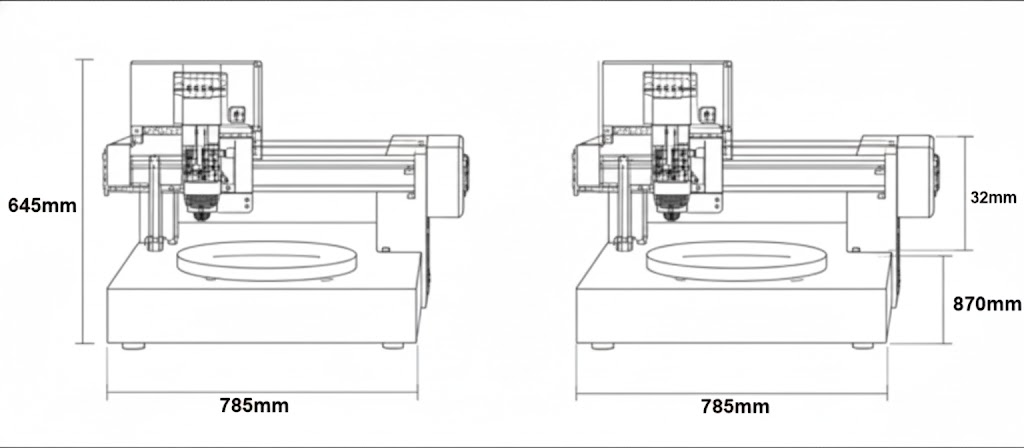

Understanding the machine's capabilities is key to evaluating its total 360 rotary uv printer cost and benefit. This uv printer cylinder combines a robust build with high-end specifications

Max Print Height: 280mm | Fits most mainstream drinkware (e.g., 500ml thermoses, 350ml mugs) and small industrial pipes. No extra modifications needed, covering 80% of cylindrical printing scenarios. |

Max Diameter: 600mm | Solves the "difficulty in printing large cylindrical objects" pain point. Enables direct printing on industrial pipes and large packaging barrels without segmental splicing. |

Ink System: UV LED Curable Inks | (CMYK + White + Varnish options) – Addresses the "poor adhesion and fading" issue. The high-opacity white ink creates a vivid base for dark/transparent substrates, while varnish adds scratch resistance. |

Print Speed: 30–50 prints/hour | Targets the customization demand for "small batches + fast delivery." 3–5x more efficient than traditional transfer printing, supporting "same-day order fulfillment." |

Net Weight: 55kg | Lighter than comparable equipment (typically over 80kg), allowing flexible placement and movement in workshops. Perfect for small-to-medium factories with limited space. |

Connectivity: USB + Ethernet | Eliminates "connection instability" during high-volume production. Dual connectivity ensures seamless data transmission, reducing downtime caused by signal interruptions. |

As a dedicated china cylinder uv printer factory, we can also discuss customization options to meet specific production needs.

Our experts answer the questions we hear most from print shop owners.

A: Yes, The uv cylindrical printer can handle "slightly irregular curved surfaces" (maximum height difference ≤3mm) – this is our exclusive optimization for "non-standard cylindrical objects." Most industry devices only support pure cylindrical printing; slight protrusions or depressions on the surface cause "ink droplet diffusion and blurriness." Our solution is "dynamic focus compensation technology": the printhead real-time detects the distance to the object’s surface and automatically adjusts inkjet focus to ensure precise ink adhesion. However, it does not support objects with "deep grooves or sharp edges" – this is a physical limitation of UV printing, not a device shortcoming

A: We use "anti-yellowing UV white ink," which has a yellowing rate of ≤0.5% after 500 hours of intense light testing – far exceeding the industry average (typically ≥2%). This solves the customization pain point of "patterns turning yellow and dull after long-term use." For example, a custom thermos cup’s white ink base remains bright even after 1 year of use, with no color fading. The core reason is that our white ink contains UV stabilizers, paired with LED cold light curing (no high-temperature damage to substrates), providing double protection for durability

A: The key difference lies in "synchronization precision" and "structural stability." Flatbed + attachment setups rely on external add-ons, leading to unsynchronized printhead and workpiece movement (common issues: banding, overlap). Our integrated system is engineered from the ground up for cylindrical work, with "dual-axis synchronous drive technology" that calibrates speed in real time (error ≤0.01mm). Additionally, the printhead height is pre-optimized for curved surfaces, avoiding the "focus inconsistency" that plagues modified flatbeds. For businesses focused on cylindrical printing, this means 30% higher efficiency and 80% fewer quality issues.

The cylindrical printing industry has long been stuck with three critical pain points: focus deviation on tapered objects, dull colors on dark substrates, and seamless joint gaps on large-diameter workpieces. Most devices are either "patched solutions" of flatbed printers plus rotary attachments or sacrifice resolution for speed. Our 360 Rotary UV Printer is an integrated system specifically engineered to solve these "industry chronicles"—and it’s the tangible embodiment of our original "Cylindrical Printing 4.0" concept (Precision Synchronization + Instant Curing + Universal Substrate Compatibility). It’s not just about "being able to print"; it’s about elevating cylindrical/curved surface printing from "barely usable" to "high-efficiency and precision" fully adapting to the mass customization production demands.

Our Printer offers high precision in printing on cylindrical and conical surfaces.It's engineered to solve the most significant challenge in cylindrical printing: maintaining high resolution and adhesion without distortion, even during a full 360-degree wrap.

Whether you're printing on tumblers, water bottles, glassware, or custom industrial components, this cylinder uv printer delivers high-resolution, vibrant prints with instant curing. The integrated uv printer with rotary attachment ensures perfect synchronization between the printhead and the item's rotation, resulting in seamless, edge-to-edge graphics that flatbed printers simply cannot achieve.

We move beyond basic specifications to focus on features that deliver real-world profitability. This machine is built for operators who demand reliability and quality.

Most cylindrical printers on the market compress resolution to 1440 DPI for speed, resulting in jagged edges on brand logos or intricate patterns within 1mm. We insist on a maximum output of 2880 DPI, paired with our exclusive "micro-droplet precision control technology." Even English initials on tumblers or gradient textures on cosmetic bottles maintain "sharp clarity when magnified 3x." This is critical for high-end customization and corporate gifts that demand "brand texture," directly reducing return rates caused by printing flaws.

Ordinary "flatbed + rotary attachment" devices suffer from unsynchronized movement between the printhead and workpiece rotation, often leading to "1mm overlap at the start and end" or "blank gaps in the middle." Our machine adopts "dual-axis synchronous drive technology"—the printhead movement speed is real-time calibrated with the workpiece's rotational angular velocity, controlling errors within 0.01mm. Whether it’s industrial pipes with a diameter of 600mm or small water cups of 100mm, it achieves "one-time molding without splicing." This is especially ideal for promotional products and packaging bottles that require full-wrap designs.

Dark metals and transparent glass have long been "color rendering nightmares" for cylindrical printing—ordinary devices either produce dull colors or suffer from poor adhesion (peeling with a touch). Our solution features an exclusive "two-step curing logic": first, a high-opacity white ink is sprayed to form an "optical base layer," instantly cured by UV light to lock it in place; then the CMYK color layer is applied, with a second curing to enhance adhesion. The result? "Vibrant, non-fading colors"—a red logo on a black tumbler stays bright, and patterns on transparent wine glasses resist wear and washing. This solves the industry pain point of "material limitations restricting design possibilities."

This printer is not only a uv rotary printer for tumblers, but also its capabilities extend far beyond that.Its adjustable system and advanced ink chemistry allow you to print directly on a vast range of substrates, including:

Glass

Stainless Steel

Coated Metals

Hard Plastics (Acrylic, PVC)

Wood (bamboo cups)

Ceramics

The cylindrical uv printer is designed for high-volume, quick-turnaround production.Its stable build, reliable components, and intuitive workflow software reduce setup time, minimize waste, and allow your business to confidently accept large and complex orders. The right features can significantly impact the long-term 360 rotary uv printer price and ownership cost, making this an intelligent investment.

This uv cylinder printer opens new markets and revenue streams. Its versatility makes it the ideal solution for multiple industries.

Custom Tumblers: Print custom designs on tumblers and drinkware with high precision and vibrant colors.

Custom Mugs: Print full-color, detailed images on ceramic mugs, coffee cups, and other cylindrical objects.

Glassware & Bottles: Ideal for printing logos, images, and text on glass bottles, wine glasses, and promotional items.

Personalized perfume bottle design: Providing perfume brands or high-end custom brands with personalized patterns and customized bottle printing (such as brand logos, limited edition patterns, etc.) for perfume bottles.

Understanding the machine's capabilities is key to evaluating its total 360 rotary uv printer cost and benefit. This uv printer cylinder combines a robust build with high-end specifications

Max Print Height: 280mm | Fits most mainstream drinkware (e.g., 500ml thermoses, 350ml mugs) and small industrial pipes. No extra modifications needed, covering 80% of cylindrical printing scenarios. |

Max Diameter: 600mm | Solves the "difficulty in printing large cylindrical objects" pain point. Enables direct printing on industrial pipes and large packaging barrels without segmental splicing. |

Ink System: UV LED Curable Inks | (CMYK + White + Varnish options) – Addresses the "poor adhesion and fading" issue. The high-opacity white ink creates a vivid base for dark/transparent substrates, while varnish adds scratch resistance. |

Print Speed: 30–50 prints/hour | Targets the customization demand for "small batches + fast delivery." 3–5x more efficient than traditional transfer printing, supporting "same-day order fulfillment." |

Net Weight: 55kg | Lighter than comparable equipment (typically over 80kg), allowing flexible placement and movement in workshops. Perfect for small-to-medium factories with limited space. |

Connectivity: USB + Ethernet | Eliminates "connection instability" during high-volume production. Dual connectivity ensures seamless data transmission, reducing downtime caused by signal interruptions. |

As a dedicated china cylinder uv printer factory, we can also discuss customization options to meet specific production needs.

Our experts answer the questions we hear most from print shop owners.

A: Yes, The uv cylindrical printer can handle "slightly irregular curved surfaces" (maximum height difference ≤3mm) – this is our exclusive optimization for "non-standard cylindrical objects." Most industry devices only support pure cylindrical printing; slight protrusions or depressions on the surface cause "ink droplet diffusion and blurriness." Our solution is "dynamic focus compensation technology": the printhead real-time detects the distance to the object’s surface and automatically adjusts inkjet focus to ensure precise ink adhesion. However, it does not support objects with "deep grooves or sharp edges" – this is a physical limitation of UV printing, not a device shortcoming

A: We use "anti-yellowing UV white ink," which has a yellowing rate of ≤0.5% after 500 hours of intense light testing – far exceeding the industry average (typically ≥2%). This solves the customization pain point of "patterns turning yellow and dull after long-term use." For example, a custom thermos cup’s white ink base remains bright even after 1 year of use, with no color fading. The core reason is that our white ink contains UV stabilizers, paired with LED cold light curing (no high-temperature damage to substrates), providing double protection for durability

A: The key difference lies in "synchronization precision" and "structural stability." Flatbed + attachment setups rely on external add-ons, leading to unsynchronized printhead and workpiece movement (common issues: banding, overlap). Our integrated system is engineered from the ground up for cylindrical work, with "dual-axis synchronous drive technology" that calibrates speed in real time (error ≤0.01mm). Additionally, the printhead height is pre-optimized for curved surfaces, avoiding the "focus inconsistency" that plagues modified flatbeds. For businesses focused on cylindrical printing, this means 30% higher efficiency and 80% fewer quality issues.