English

T: +86-180-0799-3137

E: info@refinecolor.com

E: info@refinecolor.com

9F, Building 25, Tian 'an Shenchuanggu, Fenggang Town, Dongguan 523703, China

Views: 0 Author: Refinecolor-Cindy Publish Time: 2025-11-06 Origin: Site

After working with 500+ print shops, signage companies, and customization factories, we’ve noticed a recurring confusion tied to specific search queries—like “texintel epson printer uv solvent thik layer braille.” This query bundles two fundamentally distinct ink technologies (UV and Solvent) under a single application: tactile, thick-layer printing. It's a common mix-up, but the technical reality is clear.

The answer is an unequivocal No. This capability is exclusive to UV printing technology. A solvent printer simply cannot build the required 'thik layer,' and understanding why is critical to avoiding costly equipment mistakes—especially for businesses searching for "texintel epson printer uv solvent thik layer braille" to fulfill client demands.

The limitation isn 't in the printer hardware, but in the chemical properties of the ink and its drying (or curing) process.

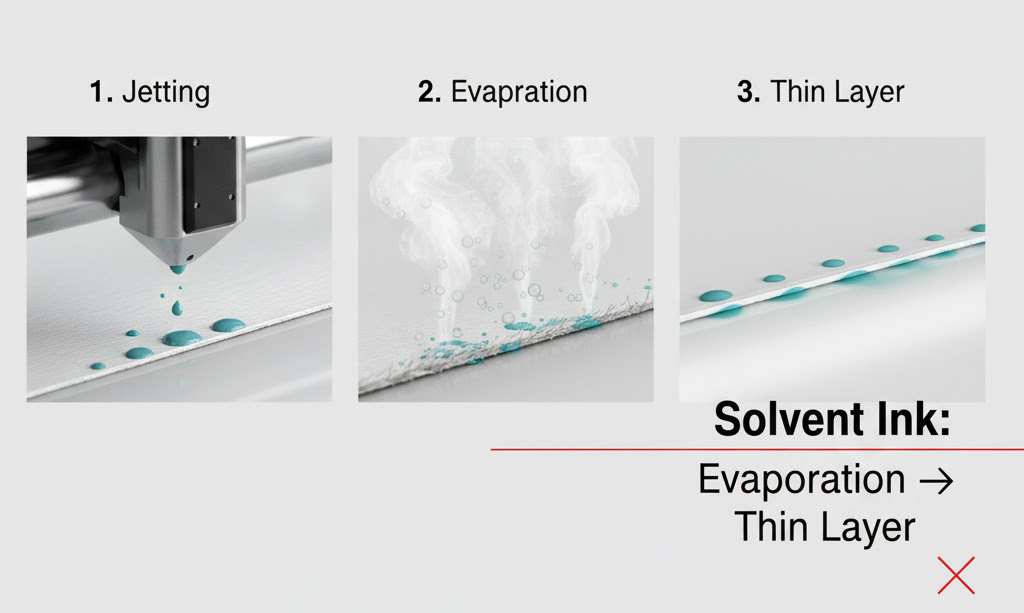

Solvent inks are engineered to be thin and penetrative. They consist of pigment suspended in a volatile solvent, designed specifically to chemically "bond" with flexible substrates like vinyl banners or vehicle wraps.

Drying Process: Relies on evaporation. After jetting, the volatile solvent evaporates into the air, leaving only a thin pigment film on the substrate.

The Critical Limitation: Evaporation makes layering impossible. Applying a second layer before the first fully dries creates a messy, uncured pool of ink that fails to adhere—ruining the print Solvent printing is inherently a single, flat-layer process, so "thik layer" or braille is technically unachievable. This is why "texintel epson printer uv solvent thik layer braille" can never lead to a solvent-based solution.

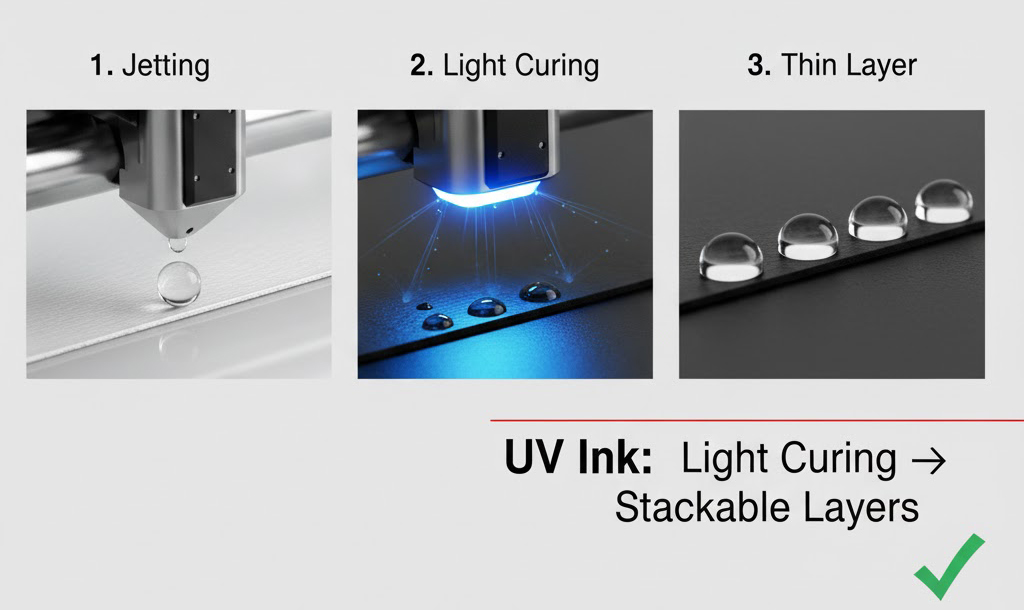

UV inks are a world apart—they're 100% solid photopolymers (liquid plastic) with no volatile solvents to evaporate.

l Curing Process: Relies on photopolymerization. As highlighted in TexIntel's industry analyses, Epson printheads are renowned for precision—they jet microscopic droplets of photopolymer ink, which are instantly hardened (cured) by a high-intensity UV LED lamp mounted with the printhead. The liquid ink turns solid in milliseconds.

l The Game-Changing Capability: Instant curing lets the printer jet a new droplet directly on top of the first—no waiting, no smudging. This is the core technology that makes "texintel epson printer uv solvent thik layer braille" a viable request—only UV can stack layers.

This instant-curing process is the secret to braille, 3D textures, and thick-layer prints. It breaks free from flat, 2D limitations.

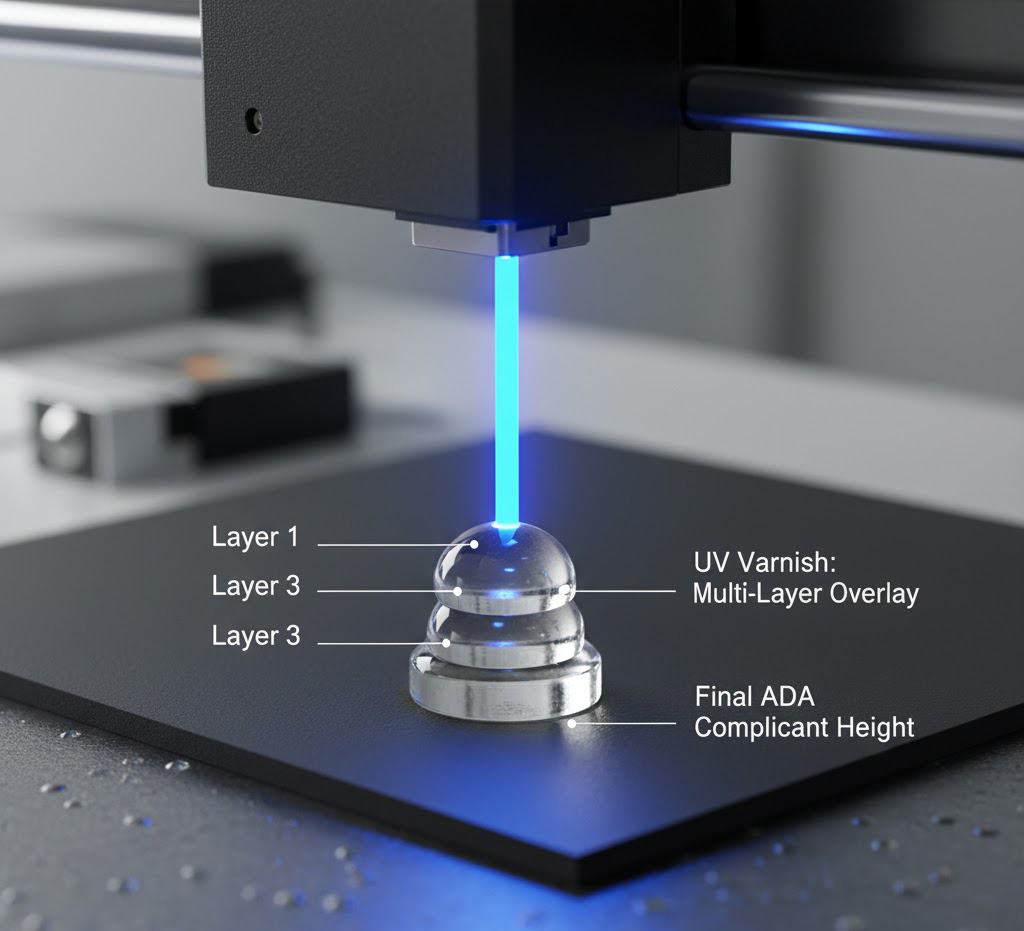

By programming the printer to pass over the same spot repeatedly, it deposits and cures layer after layer of clear varnish (or ink)—a technique called "multi-layer overlay".

Precision is unmatched: A professional UV flatbed printer can be calibrated to build braille dots to the exact height and spacing required for ADA compliance. For solvent printers, which depend on evaporation, this level of control is impossible. So while “texintel epson printer uv solvent thik layer braille” mixes two technologies, the only technical solution is UV.

If your business needs ADA-compliant signage, textured packaging proofs, or any product requiring a tangible "thik layer," a solvent printer won't deliver.

What you need is a UV flatbed printer with a varnish channel.

This configuration lets you print full-color graphics and build tactile braille layers in a single, efficient pass—directly addressing the core need behind “texintel epson printer uv solvent thik layer braille.” To explore equipment built for this exact application, we invite you to explore our complete collection of UV Flatbed Printers.

Refinecolor Printer will meet you at the ISA Expo in the USA

Refinecolor Printer Attending 2025 SAUDI SIGNAGE & LABELLING EXPO

How Does The UV Printer’s Vision Positioning CCD System Work?

Refinecolor and Epson China participated in the CHN GIFT EXPO in Shanghai

UV Printing Future: The Integration of UV Printing And Laser Cutting in One Machine

UV Label Printer Vs UV DTF Printer: Choosing The Best Solution for Your Business