English

T: +86-180-0799-3137

E: info@refinecolor.com

E: info@refinecolor.com

9F, Building 25, Tian 'an Shenchuanggu, Fenggang Town, Dongguan 523703, China

Views: 0 Author: Refinecolor-Eason Publish Time: 2025-10-10 Origin: Site

As someone who's worked with clients across various industries, I've seen firsthand how the longevity of printed materials can make or break a brand's image. I've often had clients who take with faded or peeling signs, frustrated with the lack of lasting quality. This isn't just an inconvenience; it's a direct hit to the reputation they’ve worked so hard to build. So how long does uv ink last? The answer often lies in the ink itself.

It's UV-curable ink. Not only is it the heart of the modern printing industry, but it’s also the guardian of every brand’s image. It promises instant drying, remarkable versatility, and most importantly—outstanding durability. But how long does it really last? Is it the set-it-and-forget-it solution everyone claims?

Lifespan is determined by multiple factors: ink formulation, substrate surface energy/roughness, curing energy, and usage environment are the four main factors.

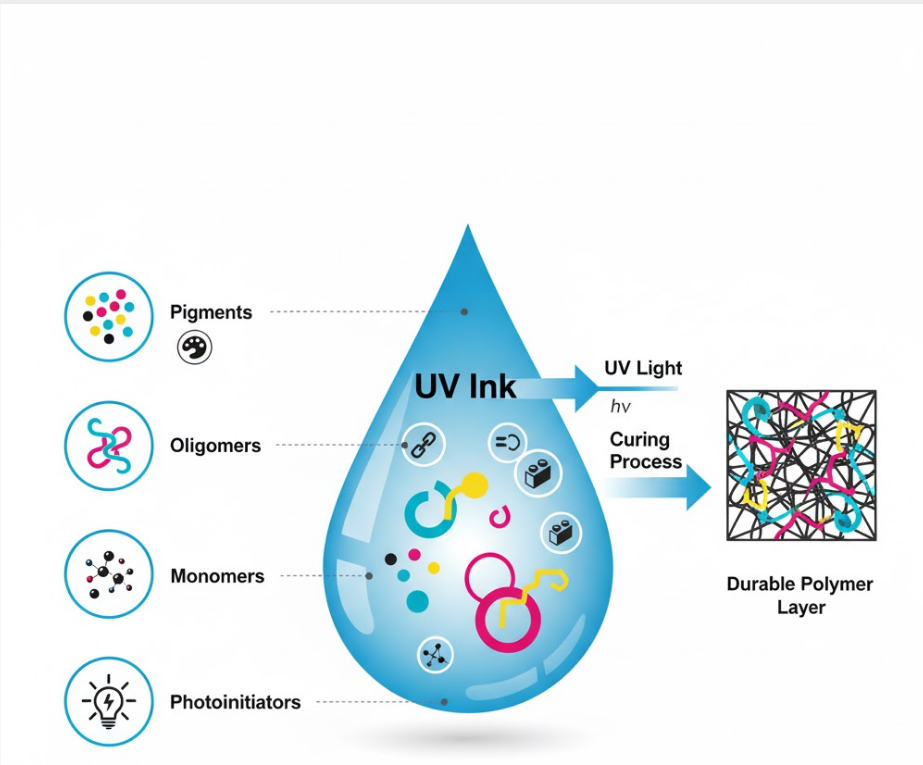

Before we can talk about how long it lasts, we need to understand what it is. Unlike the traditional inks you might have in your desktop printer, which dry through solvent evaporation, UV inks are acrylic systems containing photoinitiators that crosslink and cure rapidly under specific wavelengths/energy densities (usually 395–405 nm LEDs or medium-pressure mercury lamps). 'Instant' is more accurately described as milliseconds to seconds.

The ink like a high-tech formula with a few key ingredients that have to work in perfect harmony

Pigments: These are the fine, solid particles that give the ink its color. The quality and type of pigment are a huge factor in fade resistance., For example, The lightfastness and dispersion of pigments play a huge role in how well UV inks resist fading. High-quality inorganic pigments like titanium white and chrome yellow tend to have better resistance to UV light, while evenly dispersed pigments with finer particles help create more stable and long-lasting colors

Oligomers & Monomers: These form the backbone of the ink. You can think of them as the liquid base or binder that holds the pigment. Monomers are smaller molecules that help control viscosity, while oligomers are larger and determine the final properties like flexibility and hardness.

Photoinitiators: These molecules are the catalyst. When high-intensity UV light hits them, they kick off a frantic chain reaction, causing the monomers and oligomers to link together instantly.

Additives: This is the secret sauce. Small amounts of other chemicals are added to improve performance—things like adhesion promoters to help the ink stick to tricky surfaces like glass, or flow agents to ensure a smooth, even finish.

Not all UV ink is created equal. It's formulated for specific jobs, and using the right one is critical. We've seen clients try to use a rigid ink on a flexible banner, and the result is a cracked, peeling mess within weeks. Here’s a quick rundown:

Hard UV Ink: The workhorse for rigid surfaces like acrylic, metal, and wood. It forms a tough, scratch-resistant layer.

Soft UV Ink: Designed for flexibility. This is your go-to for printing on leather, banners, and other materials that need to bend and stretch without cracking.

Transparent UV Ink: Used for creating glossy varnish effects or protective clear coats. It can add a premium, high-impact finish to prints.

Ordinary UV Ink: A general-purpose ink that balances cost and performance for a wide range of standard applications.

High-Strength UV Ink: It’s formulated for maximum adhesion and resistance to chemicals and abrasion, often used for industrial parts or membrane switches.

Eco-friendly UV Ink: These newer formulations have low-to-zero Volatile Organic Compounds (VOCs), making them safer for operators and the environment.

UV Ink of Special Effect: This category includes inks that create textures, fluorescent effects under blacklight, or other unique visual properties.

You can think of it as a film forming from a liquid into a cross-linked network; at 395 nm with irradiance around 8–16 W/cm² and a web speed of about 0.8–1.5 m/min, full cure is achievable (example settings—tune to your ink and machine).

Traditional solvent-based inks dry slowly as their chemical carriers evaporate into the air, leaving the pigment behind. This can take hours, releases VOCs, and the final print is often less durable.

UV ink, on the other hand,The 100% solid ink layer is bonded to the substrate through that curing process, making it incredibly resistant to scratches, solvents, and weather

Okay, now you know what it is. But is it the right choice for your operation? Let's break down the good, the bad, and the technical.

Key Features:

Viscosity: UV inks are typically thicker than solvent inks. This means they don't get absorbed into the substrate as much, instead sitting on top. This is great for vibrant color on non-porous materials but requires printheads designed to handle higher viscosity like epson i3200

Curing Method: Requires a UV light source (either traditional mercury-arc lamps or modern LED systems) integrated into the printer. The lamp's power, wavelength, and distance from the substrate must be perfectly calibrated.

Printer Compatibility: You can't just pour UV ink into any printer. It requires a machine specifically built for it like refinecolor printer(内链), with compatible printheads, ink lines, and a curing system.

Pros:

Fast Curing: This is the biggest productivity booster. Prints are 100% cured the second they come off the press. ship them immediately. No more racks of prints waiting to dry.

High Durability: The cross-linked polymer is tough. It resists fading, scratching, and chemical exposure far better than traditional inks.

Multi-material Compatibility: This is where UV ink truly shines. Because it sits on the surface and is instantly bonded, you can print high-quality images on a staggering range of materials: glass, metal, wood, plastic, ceramics, leather—you name it.

Cons:

High Cost: To be honest, the upfront cost per liter for UV ink is higher than for solvent inks. You're paying for the advanced chemistry.

Requires UV Lamp: This means specialized, more expensive equipment. The lamps also consume energy and have a limited lifespan, representing an ongoing operational cost.

Volatile: While much better than they used to be, some UV inks can still have a distinct odor and contain irritants. Proper ventilation and personal protective equipment are non-negotiable.

Here’s where the rubber meets the road. A print’s lifespan depends entirely on its environment. There is a big difference between indoor and outdoor

For things like office signage, retail displays, and product labels, you’re in the best-case scenario. Shielded from UV radiation and harsh weather, a quality UV print can easily last 5–8 years with minimal, if any, noticeable fading. It’s highly resistant to smudging and cleaning.

This is the ultimate test. For billboards, construction site banners, the primary enemies are sunlight and rain. Standard UV inks typically last 2–5 years before significant fading occurs. However, premium inks formulated and paired with a protective UV-blocking laminate can push that lifespan up to 10 years.

Let's clarify this one. The chart mentions "UV Tattoos" with a 5-8 year lifespan. This refers to permanent tattoos that use UV-reactive pigments, which are invisible in normal light but glow under a blacklight. Their longevity is a subject of debate in the tattoo world, as the pigments can be broken down by sunlight over time, just like regular tattoo ink. Temporary, sticker-like UV tattoos for parties will only last a few days.

When you're printing on machine parts, control panels, or electronics, durability is about more than just looks—it's about legibility and safety. UV ink excels here due to its incredible adhesion to metal and plastic and its resistance to oils and solvents. These prints can often last the lifetime of the product itself, easily 8–10 years.

Printing on fabrics, leather, and garments with flexible UV inks is a growing market. The key here is washability and crack resistance. A well-cured print can withstand dozens of wash cycles, but its lifespan is ultimately tied to the life of the garment itself.

Think phone cases, golf balls, and custom glassware. The challenge is adhesion to diverse and sometimes oddly shaped surfaces. With the right pre-treatment (like a primer or flame treatment), UV ink forms a tenacious bond that resists the scuffs and scrapes of daily use.

This question has two answers: the lifespan of the printed product (which we just covered) and the shelf life of the liquid ink in the bottle. Both are critically important.

Lifespan/Shelf Life Overview

Unopened, properly stored UV ink typically has a shelf life of 12 to 18 months. The photoinitiators and other reactive components can degrade over time, even in a sealed container.

Storage Conditions: Temperature, Light, and Sealing

I can't stress this enough: storage is everything. You should treat your UV ink inventory like perishable goods.

Temperature: Store it in a cool, stable environment, ideally between 15°C and 25°C (60°F - 77°F). Too hot, and you risk starting the polymerization process in the bottle. Too cold, and the viscosity can increase, causing printing problems.

Light: Keep it in a dark place, away from any sunlight or UV sources. UV ink is designed to react to UV light, and even ambient sunlight contains enough to begin degrading the ink over time.

Sealing: Always keep the bottle tightly sealed. This prevents oxygen from interacting with the ink and stops key components from evaporating.

Reasons for Short Lifespan of Large-Capacity Ink

I've noticed that some clients using large, 5-liter ink jugs report issues faster than those using 1-liter bottles. This is often due to pigment settling. Over time, the heavy pigment particles can settle at the bottom. If the ink isn't properly agitated before use (gently rolled, never shaken!), you'll get inconsistent color density and may even starve the printheads of pigment.

Once the ink is on a substrate, a new set of variables comes into play.

Ink Quality: This is the number one factor. Premium inks use high-grade, automotive-quality pigments that are engineered for lightfastness. Budget inks often use cheaper organic pigments that will fade much, much faster when exposed to sunlight. You absolutely get what you pay for.

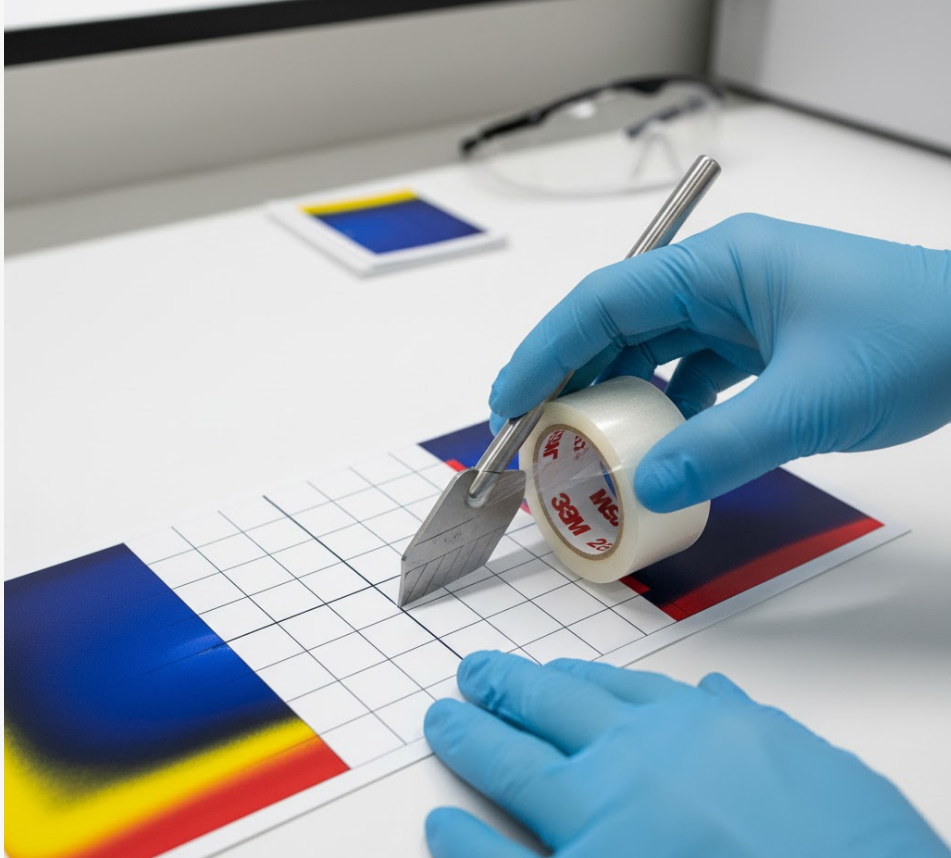

Curing Process: An improperly cured print is a failed print. Under-curing (not enough UV exposure) leaves the ink soft, tacky, and easy to scratch off. Over-curing (too much UV exposure) can make the ink brittle and prone to cracking, especially on flexible materials. The UV lamp's intensity and the print speed must be perfectly matched to the ink and substrate.

Environmental Conditions: The big enemy is direct sunlight. The UV radiation in sunlight is relentless and will eventually break down any pigment. High humidity can interfere with adhesion on certain substrates, and extreme temperature cycles can cause the substrate and ink to expand and contract at different rates, leading to cracking or peeling.

Substrate Material: Ink adheres differently to different surfaces. A porous material like wood will create a strong mechanical bond. A non-porous surface like glass requires excellent chemical adhesion, often boosted with a primer. If the bond between ink and substrate is weak, the ink will fail, no matter how good it is.

Application Technique & Maintenance: A thin, even layer of ink is usually more durable than a thick, heavy deposit. For ultimate longevity in harsh environments, nothing beats a post-print protective coating, like a clear varnish or laminate. This acts as a sacrificial layer that absorbs UV damage and abrasion.

The following is the suggestion we give our partners to get the most life out of their prints.

Proper Substrate Preparation: Always start with a clean, dry, and grease-free surface. For non-porous materials like glass or metal, use the recommended adhesion promoter or primer.

Correct Curing and Exposure: Profile your printer for each ink/substrate combination. Run adhesion tests (like the cross-hatch tape test) to ensure you have a full, proper cure. Don’t just eyeball it.

Protection from Sunlight and Moisture: For outdoor applications, position signage to minimize direct afternoon sun exposure if possible. More importantly, sell your clients on the value of a UV-blocking laminate. It’s a small upfront cost that can double the life of a print.

Regular Maintenance for Printed Materials: Advise clients to clean prints gently with a soft cloth and mild soap and water. Avoid abrasive cleaners or pressure washers, which can damage the ink layer.

Storage Tips for UV Ink: Reiterate the mantra: cool, dark, and sealed. Rotate your stock to use the oldest ink first (FIFO - First In, First Out).

When I worked on a similar project for a beachfront café, we chose a premium ink based on the location’s harsh environmental conditions. I’ve learned that when dealing with coastal areas with high UV exposure and saltwater, investing in marine-grade ink isn't just a suggestion—it's a necessity for long-term client satisfaction.

Case Study: The Tale of Two Café Signs

Location: Clearwater, Florida (high UV index, salt spray)

Project: a beachfront café, "The Salty Bean," ordered two identical 4'x8' outdoor signs printed on aluminum composite panels.

Purchase on March,2018.Printed with a standard, mid-range UV ink,Cost: $450. after one year they find their sign is fading.they have to buy another one from our agent on Aug,2020, and Printed with a premium, marine-grade flexible UV ink and finished with a UV-protective laminate,Cost: $620.their second sign still work at now

Why the second sign work so long?Firstly our agent applied a 2K automotive-grade clear coat after printing. The clear coat was cured using a UV curing chamber set to 100W/cm² intensity with a wavelength range of 320-400nm. The curing time was set for 60 seconds per side, ensuring a complete protective layer over the print.oA UV protective laminate was also added to provide an extra layer of abrasion resistance and UV blocking.

Results:

We've touched on this, but it's so critical to profitability that it deserves its own section. Using expired ink is one of the most common—and costly—mistakes we see new print shops make.

The typical shelf life is 12–18 months. The "best by" date on the bottle isn't a suggestion; it’s a warning. After that date, the ink's chemistry begins to break down. The photoinitiators lose their potency, which means the ink won't cure properly, leading to tacky prints. The viscosity can also change, and the pigments can clump together into a sludge.

Risks of using expired ink:

Poor Print Quality: Inconsistent colors, banding, and poor adhesion.

Printer Damage: The biggest risk. Clumped pigment and altered viscosity can irreversibly clog the delicate nozzles in your printheads. A single clogged head can cost thousands of dollars to replace, wiping out the profit from dozens of jobs.

Proper storage methods: Store bottles in a dedicated, climate-controlled cabinet. Before use, don’t shake the bottle—that introduces bubbles. Instead, gently roll or rock it for a few minutes to re-suspend the pigments evenly.

In a crowded market, how do you know if an ink is high quality? Look for certifications. They are an independent verification of quality, safety, and consistency.

ISO 9001: This shows the manufacturer has a rigorous quality management system in place. It means they have processes to ensure every batch of ink is consistent.

RoHS (Restriction of Hazardous Substances): This is a big one. It certifies that the ink is free from specific hazardous materials like lead, mercury, and cadmium. This is crucial for products that might be handled by consumers.

REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals): A European regulation that ensures a high level of protection for human health and the environment from the use of chemicals.

These certifications aren't just fancy logos. They are a sign that you're buying from a reputable manufacturer who invests in quality control and safety, which directly translates to better, more reliable ink performance.

Let's clear the air on a few common questions.

They are very similar. The difference is the light source used for curing. Traditional UV printers use broad-spectrum mercury-arc lamps, while newer machines use LEDs (Light Emitting Diodes). LEDs are more energy-efficient, last longer, and produce less heat. However, they emit a narrower band of UV light, so the ink must be specifically formulated with photoinitiators that react to that exact wavelength.

Generally, no. The curing process creates a permanent, cross-linked polymer. It's designed to be permanent. While aggressive chemical solvents can sometimes remove it, the process is harsh and often damages the underlying substrate.

Not necessarily. In fact, an excessively thick layer of ink can be detrimental. It can be difficult to cure all the way through, leaving a soft layer underneath, and it can become brittle and prone to cracking. The key is the optimal thickness for full curing and flexibility.

Talk to your supplier! The choice depends entirely on the substrate and the end-use. Is it rigid or flexible? Indoor or outdoor? Will it be exposed to chemicals? A good partner will help you match the right ink to the right job.

Absolutely not.Printers and printheads are designed to work with inks of a specific viscosity, particle size, and chemical composition. Using an unapproved ink can cause catastrophic damage to your printheads. Stick with OEM ink or a reputable third-party ink that is certified for your specific machine.

First, check the expiration date. If it's old, toss it. Before pouring, look at the ink. Does it look separated, clumpy, or like sludge?

If so, don't use it. When in doubt, run a small test print. If it looks good and passes an adhesion test, you're likely good to go.

Visualizing lifespan data can make it easier to explain to clients. Here's a simple breakdown of expected durability across common applications based on real-world performance.

So, how long does UV ink last? The answer is clear.It depends on the quality of the ink you buy, the surface you print on, the precision of your curing process, and the environment your print lives in. UV ink isn't just a consumable; it's a critical component in an advanced printing system. When you understand the science and respect the variables, you can unlock its incredible potential for durability.

By investing in premium inks, perfecting your application process, and educating your clients on an item's real-world lifespan, you move from simply selling prints to providing long-term, high-value solutions. And that's how you build a reputation that truly lasts.

Refinecolor Printer will meet you at the ISA Expo in the USA

Refinecolor Printer Attending 2025 SAUDI SIGNAGE & LABELLING EXPO

How Does The UV Printer’s Vision Positioning CCD System Work?

Refinecolor and Epson China participated in the CHN GIFT EXPO in Shanghai

UV Printing Future: The Integration of UV Printing And Laser Cutting in One Machine

UV Label Printer Vs UV DTF Printer: Choosing The Best Solution for Your Business

content is empty!