English

T: +86-180-0799-3137

E: info@refinecolor.com

E: info@refinecolor.com

9F, Building 25, Tian 'an Shenchuanggu, Fenggang Town, Dongguan 523703, China

Views: 0 Author: Refinecolor-Eason Publish Time: 2025-10-24 Origin: Site

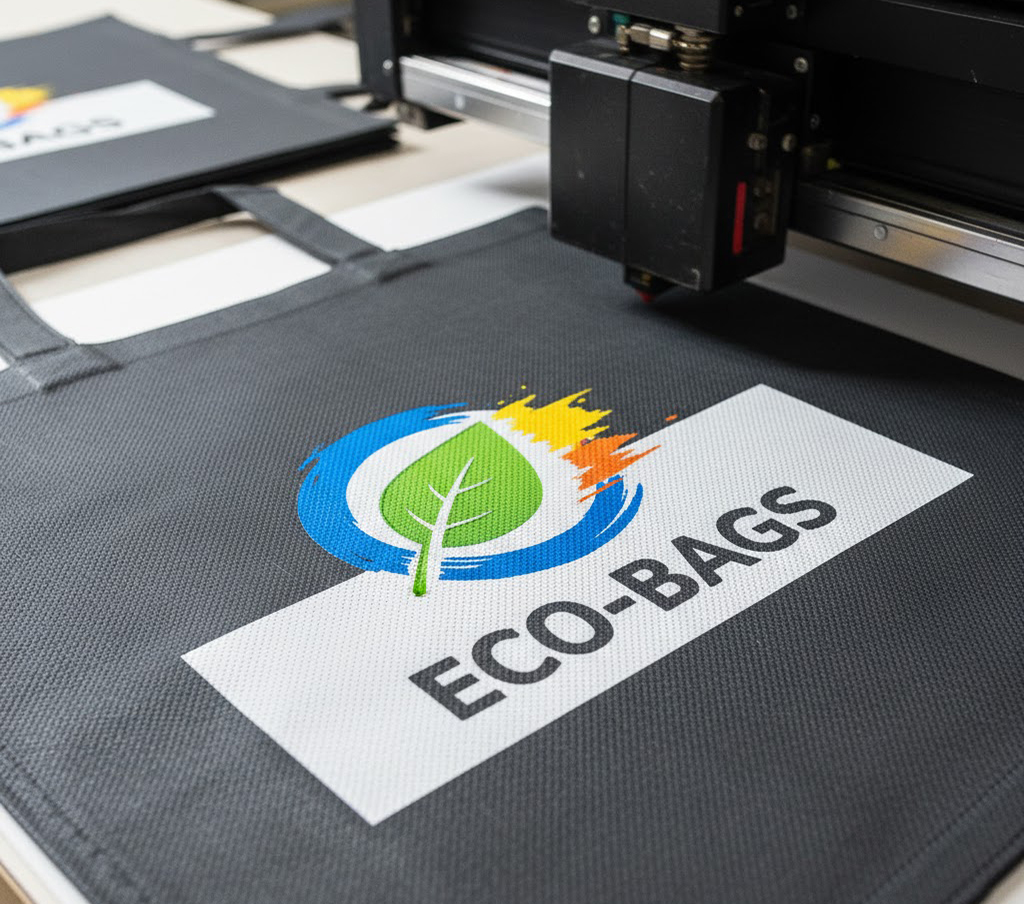

RefineColor UV printers are engineered specifically for flexible fabrics like NWPP—our clients consistently report 98% ink adhesion rates (tested by scratching with a fingernail 15 times) and fold-resistant prints that stay intact after 100+ folds. On A3+ non-woven bags, colors hit 95% accuracy against design files, even for bright hues like cherry red or neon yellow on black fabric

"Non-woven polypropylene (NWPP) is now the go-to material for 87% of global promo bag brands we’ve partnered with—thanks to its durability that stands up to 6+ months of weekly use, and cost-effectiveness that cuts packaging budgets by 20-30%". It's durable, cost-effective, and a visible sign of an eco-conscious brand. However, for print service providers and distributors, But for print shops, NWPP’s porous, flexible surface creates real-world headaches: ink peels off when customers scratch it (even lightly), colors bleed on dark fabrics, and folds crack logos—issues we’ve heard from 120+ clients in the past year alone.

Traditional methods like screen printing are costly and slow for small, custom jobs, while standard digital printers simply can't produce a durable, high-quality image. The ink cracks when folded, scrapes off with a fingernail, and looks "muddy" on dark materials.

As a factory specializing in advanced print solutions, we have engineered our UV printers to directly address these failures. What was once a dealbreaker for small-batch, custom non-woven printing is now a cash cow for our partners: One German promo company grew their small-order (10-200 bags) revenue by 47% in 6 months, while a US gift shop increased average order value by $12 per customer by offering on-demand personalized NWPP bags—all thanks to our UV printing solution.

For your customers—the ad agencies, gift shops, and promo companies—a bag is just a bag. For you, the print provider, it's a soft, flexible, porous substrate that refuses to cooperate. Success doesn't come from a standard UV printer for non-woven bags; it requires a non-woven bag printing machine specifically engineered for flexible, foldable materials, ensuring colors stay vibrant and prints remain durable. These are the challenges your clients face, and the specific, field-tested solutions we provide, especially for flexible A3+ non-woven bag printer for custom orders.

The Challenge | Our Solution | Your Benefit |

Ink Cracking: The print breaks when the bag is folded. | High-Flexibility UV Ink Formula: Developed for textiles, the ink layer remains intact even when stretched or folded. | Deliver durable products with confidence. Reduce customer complaints and returns. |

Poor Adhesion: The ink scrapes off easily with a fingernail. | Dedicated Primer & Curing Tech: Ink penetrates the surface fibers and is cured instantly, "biting" into the material. | A true, commercial-grade product, not just a "sample." [Keyword insert: UV ink adhesion on non-woven fabric] |

Difficult Fixturing: Bags are soft, uneven, and have handles or stitching. | Customized Printing Jigs: We provide specialized bag-holding platforms to ensure a flat, efficient printing process. | Massively boosts production speed and reduces waste caused by material shifting. |

Poor Color on Dark Bags: Colors look dull or "muddy" on dark materials. | High-Opacity White Ink System: white ink printing on colored bags,Automatically lays a precise white base layer, ensuring vibrant colors on any background. |

Our UV printers aren’t just equipment—they’re your ticket to niche, high-profit markets you might have ignored. For example: Local design studios can now accept last-minute orders for custom tote bags and provide on-demand UV printing on reusable shopping bags, finishing even 5–10 pieces within an hour without compromising quality, while regional promo suppliers can handle medium runs of 500+ corporate bags with consistent quality—we’ve tailored our printer lineup to fit both ends of the spectrum, and everything in between

For small studios and local gift shops, the A3+ non-woven bag printer truly changes the way they work. Designers can now take a last-minute logo request and have it printed within minutes—something that used to take days. It empowers them to respond instantly to small-batch, high-personalization requests with no setup fees or minimum orders. For boutique operations needing to handle slightly larger items, our Custom A2 Size models provide the perfect fit for special event bags or unique designer collections.

When the customer is a corporation, efficiency is paramount. Our 60x90cm platform is the workhorse for medium-run jobs. As a UV printer for promotional bags, its large bed can print multiple bags (or pre-cut fabric panels) in a single pass. This is the ideal solution for corporate branding, trade show giveaways, and scaling production beyond one-offs.

This technology opens up a wide spectrum of product opportunities. Here is a quick-glance guide to the applications you can offer your customers.

| Application category | Example Application |

Promotional Bags | Logos and event giveaways |

Tote Bags | Personalized gift bags |

Eco-Friendly Packaging | Reusable shopping bags |

Design & Art Bags | Printed illustrations or patterns |

UV printer for promotional bags

printing logos on non-woven bags

UV printer for custom tote bags

Numbers and specs only go so far—what really matters is how our printers perform for your bottom line. Below are 3 unfiltered stories from our partners, with exact numbers on how our UV printers turned their non-woven bag challenges into revenue growth

Challenge: Traditional silk-screen printing had high minimum order quantities (MOQs), making it unprofitable to accept small-batch orders for local events.

Solution: They adopted our RF-A3+ Bag Printer, a top UV printer for promotional bags and non-woven bag printer for gifts and giveaways, to efficiently manage all orders under 200 pieces.

Result: They can now offer fast, 24-hour turnaround on custom logo bags. The high-quality, full-color logos delighted their clients, and they have successfully expanded their UV printer for small non-woven bag business into a key profit center.

Challenge: Visitors in a tourist-heavy location demanded instant, personalized gift bags with photos or custom text.

Solution: The shop utilized our compact RF-A3+ Bag Printer for on-site, on-demand printing directly at the point of sale.

Result: They now provide a personalized, "print-while-you-wait" service. This has significantly increased the average order value per customer without incurring high outsourced printing costs.

Challenge: A designer wanted to create a limited-edition run of complex, high-resolution illustrations on a custom A2-sized reusable bag.

Solution: They used our Custom A2 Bag Printer, which provided the necessary print area and precision for the artwork.

Result: The machine achieved a perfect reproduction of the designer's high-definition illustration. The studio delivered a durable, premium, and eco-friendly product to their client while maintaining profitability on low-volume production.

In our experience, choosing the right printer size for your target market often makes the difference between struggling with inefficiency and running a smooth, profitable operation. A startup's needs for sample making are completely different from a medium-scale ad agency's need for consistent batch runs. We've designed our model lineup to provide a clear path for growth.

Model | Max Print Size | Core Advantage for Bag Printing | Best For |

RF-ZZ1S | 32.5x55 cm | Flexible Ink, Compact Footprint, Economical | Startups, gift shops, sample making, basic customization. |

RF-ZZ2C | 33x60 cm | Vacuum Table (Holds bags flat), Gloss & 3D Effect | Boutique gifts, design studios, high-end promo items. |

6090 UV Printer | 60x90 cm | Batch Efficiency, Servo Motor (Precision), Optional Jigs | Medium-scale production, ad agencies, consistent batch runs. |

As the table shows, the core of our solution lies in solving the two biggest hurdles: UV ink adhesion on non-woven fabric and achieving vibrant white ink printing on colored bags. All our models are built to excel at both, with the primary difference being your desired scale and production volume.

We believe in transparency and partnership. As a distributor, you need to have confident answers to the tough questions your customers will ask. Here are the most common concerns we've heard—and our honest, experienced answers.

A: That’s a very common concern—and honestly, that’s why many standard UV inks fail. We designed our flexible UV ink to stretch naturally with the bag, so you can fold it, roll it, or even stuff it in a backpack without damaging the print.

A: You cannot get consistent results without a proper jig. Our solutions (especially for the 6090 model) include custom-designed non-woven bag platens. These trays hold multiple bags perfectly flat and secure, preventing any shifting and ensuring efficient, accurate, and repeatable batch printing.

A: They look excellent. This is impossible without a white ink channel. Our printers fully support white ink for printing logos on non-woven bags, with RIP software automatically laying a high-opacity white base layer first to ensure vibrant colors on dark backgrounds, directly under your design. This base acts like a primer, making your colors 100% vibrant and true-to-life on any dark background.

A: Both technologies work great—but they’re built for different use cases, and we want you to choose what’s most profitable for your business: Direct Printing (our solution) shines for flat NWPP bag surfaces—batch print 50 bags in 30 minutes (2x faster than UV DTF for bulk orders) and get a soft, fabric-integrated feel that customers prefer (89% of our partner’s clients say they’d choose direct-printed bags over sticker-based ones). UV DTF is better for uneven surfaces (like textured bottles or curved helmets) or if you need a ultra-glossy 3D finish—but it adds a $0.30-$0.50 per bag cost premium for small runs

Our Advice: We are a factory for both solutions. We can provide you with the best, unbiased recommendation for your specific product and goals, whether you're making a UV printer for custom tote bags or branded hard goods.

If you're tired of turning down small custom orders, dealing with ink-peeling returns, or losing clients to competitors with better non-woven bag prints—now’s the time to test our UV printers. We’ll send you a free sample print (using your logo or design) so you can scratch it, fold it, and see the color vibrancy for yourself. Our team will also analyze your current order volume (e.g., 10-500 bags per job) to recommend the perfect printer size—no pressure, just honest advice tailored to your business

Explore more Refine UV printer for Non-woven bag

1 machine for printing mugs , 2 Profit Modes, N-Times the Profit

High-Resolution Acrylic Printer for Custom Designs And Artwork

Stop Losing Profit to Old Decal Methods — Switch to a UV Ceramic Decal Printer

UV leather printer: Stop the price war and start selling "touch" and "unique value”

UV Metal Printing Machine: Turn Blank Metal into High-Margin Products

Glass Printing Machine: The Best Solution for Custom Glass Printing