English

T: +86-180-0799-3137

E: info@refinecolor.com

E: info@refinecolor.com

9F, Building 25, Tian 'an Shenchuanggu, Fenggang Town, Dongguan 523703, China

Views: 0 Author: Refinecolor-Eason Publish Time: 2025-10-03 Origin: Site

With a decade of expertise in UV DTF Printing, Refinecolor provides tools and support for creators who want to turn anything into art.

In the dynamic world of custom decoration and product personalization, a groundbreaking technology has emerged, offering unparalleled versatility and quality: UV Direct-to-Film (DTF) Printing. This innovative method is not merely an incremental improvement over existing techniques; it represents a paradigm shift, empowering businesses to create vibrant, durable, and textured designs on a virtually limitless range of hard surfaces.

At its core, UV DTF printing is a process that uses ultraviolet (UV) curable inks to print a design onto a special adhesive-backed sheet, known as 'A' film. This printed design is then laminated with a 'B' film, creating a robust, transferable decal. This decal can then be applied to almost any hard object—glass, metal, wood, plastic, ceramic, and more—without the need for heat presses or complex pre-treatments. The result is a crisp, brilliant graphic that appears as if it were printed directly onto the object, complete with a glossy, varnish-like finish and a tangible 3D texture.

The immense popularity of UV DTF printing stems from its ability to solve several long-standing challenges in the customization industry. Previously, decorating irregular, curved, or heat-sensitive items was difficult, costly, or impossible. UV DTF bypasses these limitations. It requires no weeding of vinyl, no messy powders, and no material-specific coatings. This opens up vast new markets for promotional products, personalized gifts, industrial labeling, and bespoke branding, making it a highly attractive and profitable venture for businesses of all sizes.

To truly appreciate the power of UV DTF technology, it's essential to understand the sophisticated yet elegant process that occurs within the printer. The magic lies in the synergy between advanced ink chemistry, precision engineering, and a multi-layered film system. The entire workflow can be distilled into four key stages: Printing, UV Curing, Lamination, and Transfer.

Printing on 'A' Film: The process begins with the 'A' film, a specialized sheet with a release liner and a layer of adhesive. A UV DTF printer, such as the Refinecolor RF-ZZ2F, feeds this film and uses its industrial-grade printheads (e.g., dual Epson XP600s) to meticulously jet layers of ink. Typically, a layer of white ink is printed first to ensure color opacity on any surface, followed by the CMYK color inks to create the design. Finally, a layer of varnish is often applied, which not only adds a protective, high-gloss finish but can also create stunning textural effects.

Instant UV Curing: Immediately after the ink droplets are jetted onto the 'A' film, they pass under a powerful UV LED curing lamp integrated into the printer's carriage. This is the critical step. The UV ink is a photopolymer, meaning it contains molecules that react and solidify almost instantly when exposed to specific wavelengths of UV light. This photochemical reaction, known as curing, transforms the liquid ink into a solid, durable layer of plastic in a fractionof a second. This instant drying prevents the ink from bleeding, ensuring exceptionally sharp detail and vibrant colors.

Automated Lamination: As the printed and cured 'A' film advances through the printer, it is automatically bonded with a 'B' film. This 'B' film acts as a transfer mask or carrier sheet. In an integrated system like the RF-ZZ2F, this process is seamless. The machine's rollers apply precise pressure to laminate the two films together, ensuring a perfect, bubble-free bond. The 'B' film adheres to the top of the cured ink and varnish layer.

Ready for Transfer: The final output is a roll or sheet of ready-to-apply decals. The design is now securely sandwiched between the 'A' film's adhesive layer on the bottom and the 'B' film's carrier sheet on top. The powerful bond is created by the combination of the specialized adhesive on the 'A' film and the incredibly durable, solid layer of cured UV ink. This construction is what allows the decal to be transferred cleanly and adhere so tenaciously to the final product.

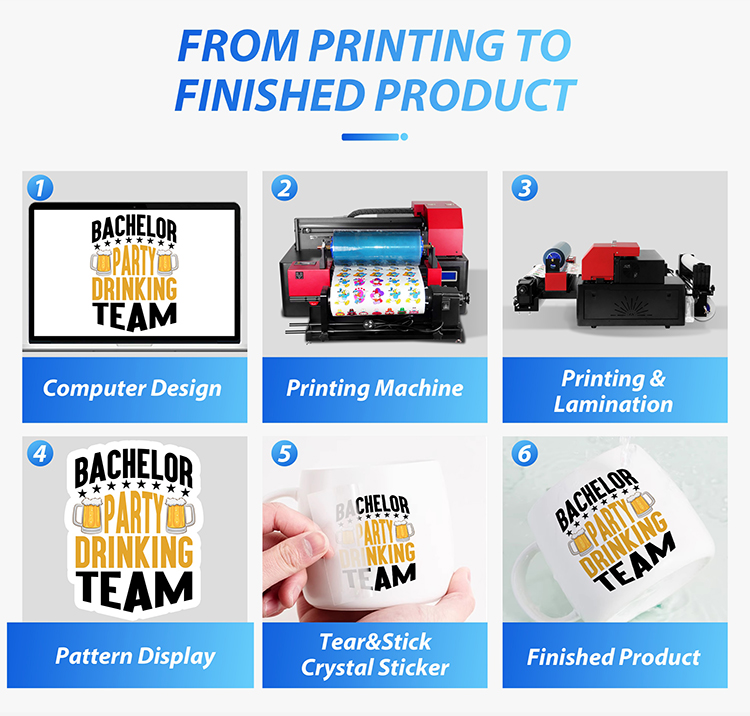

Moving from principle to practice, the operational workflow of UV DTF printing is remarkably straightforward, especially with modern, integrated machinery. Here is a detailed, step-by-step guide to creating a professional-quality UV DTF transfer.

Before any printing occurs, your digital artwork must be finalized. This is done using specialized Raster Image Processor (RIP) software, such as the Riprint software bundled with Refinecolor printers. In this stage, you arrange your designs, set color profiles, and configure the ink layers. Crucially, this is where you specify the application of white ink (as a base) and varnish (as a top coat). For example, you can choose to apply varnish over the entire design for a uniform gloss or only on specific elements to create unique textures. Once the file is prepared, it's sent to the printer.

With the design loaded, you initiate the printing process. The roll-to-roll system of the Refinecolor RF-ZZ2F automatically feeds the 'A' film into the printing path. The dual Epson printheads begin their work. The first head jets the white ink and CMYK color layers, while the second head applies the protective varnish. As the print carriage moves, the onboard UV LED lamp instantly cures each section of the design, locking in the colors and details with micron-level precision. This integrated printing and curing ensures a flawless, durable print every time.

This step, which once required a separate machine, is now fully automated in advanced systems. As the printed 'A' film exits the printing area, it is guided directly into the lamination unit. Here, the 'B' film (the carrier sheet) is fed from its own roll and pressed firmly onto the printed side of the 'A' film. The machine's pressure rollers ensure a perfect adhesion between the 'B' film and the top layer of cured varnish. The combined, laminated film is then wound onto a take-up reel, producing a finished roll of UV DTF transfers.

The final step is the manual application of the decal. Cut the desired design from the roll. Peel away the 'A' film backing paper, exposing the sticky adhesive underneath the cured ink. Carefully position the decal on your target object—be it a cup, a phone case, or a metal plaque. Press it down firmly, rubbing across the entire surface with your fingers or a squeegee to ensure the adhesive makes full contact and to eliminate any air bubbles. Finally, slowly and carefully peel off the 'B' film carrier sheet. The vibrant, glossy design remains, perfectly bonded to the object's surface.

The application of a UV DTF transfer is a clean, simple, and satisfying process that requires no specialized equipment like heat presses. The decal's ability to adhere so firmly is a result of the technology's clever design, combining a powerful adhesive with a resilient, cured ink layer.

To apply the transfer to a product like a cup, glass bottle, or metal sheet, you start by ensuring the target surface is impeccably clean and dry. Any dust, oil, or residue will compromise the adhesion. Next, you cut out your decal and peel off the backing ('A' film), revealing the adhesive. You then carefully place the sticker onto the object. Once positioned, you must apply firm, even pressure across the entire design. This activates the pressure-sensitive adhesive, forcing it into the microscopic pores of the surface and creating a powerful molecular bond.

The reason it adheres so firmly is twofold. First, the specialized adhesive is engineered for aggressive, permanent bonding to a wide variety of non-porous substrates. Second, the design itself—the layer of UV-cured ink and varnish—is essentially a thin, flexible yet incredibly tough sheet of plastic. This solid layer provides structural integrity to the decal, preventing it from tearing during application and protecting the adhesive bond from the elements once applied.

A key advantage is that no heat pressing is required. The curing of the ink happens inside the printer via the UV lamp, and the adhesion is pressure-based. This is what allows for application on heat-sensitive materials like certain plastics or electronics. While the ink itself is cured instantly, the adhesive bond strengthens over time, typically reaching its maximum strength within 24 hours. Once fully set, the transfer is exceptionally durable, scratch-resistant, and waterproof.

Transforming a blank product into a high-value custom item is at the heart of the UV DTF business model. Here's a practical guide focused on application and best practices.

Design &Print: Create your graphic in the RIP software and send it to your UV DTF printer. The machine prints the color, white, and varnish layers onto the adhesive 'A' film and automatically laminates the 'B' film on top.

Cut &Prep: Cut the finished decal from the roll. Thoroughly clean the surface of your target product (e.g., a phone case, cup, or wooden plaque) with isopropyl alcohol to remove any oils or dust.

Apply &Press: Peel the 'A' film backing to expose the adhesive. Carefully align and place the decal. Use a squeegee or your fingers to rub firmly over the entire design, working from the center outwards.

Reveal: Gently peel off the top 'B' film carrier sheet. The design will remain perfectly affixed to the product.

On a Cup or Mug: When applying to a curved surface, start by pressing down the center of the decal first. Then, slowly work your way outwards, smoothing the decal around the curve to prevent wrinkles or bubbles.

On a Phone Case: Ensure the case is perfectly clean. For designs near the edges, pay extra attention to pressing down firmly to secure the corners.

On Wood: For unfinished or porous wood, the adhesive will form an extremely strong bond. On sealed or varnished wood, a thorough cleaning is essential for optimal adhesion.

Avoid Bubbles: Always apply pressur from the center of the decal and move outwards. If a small bubble appears, you can sometimes use a very fine pin to prick it and press the air out.

Improve Stability: After applying the decal, let it rest for 24-48 hours before subjecting it to heavy use or washing. This allows the adhesive to fully cure and achieve maximum bond strength.

Don't Touch the Adhesive: Handle the decal by the edges to avoid getting fingerprints or oils on the adhesive layer, which can weaken the bond.

For distributors and agents, understanding where UV DTF fits in the technological landscape is key to identifying sales opportunities.

The primary difference is their application. Traditional DTF is for textiles (T-shirts, hoodies, fabrics). It uses water-based textile inks and a hot-melt adhesive powder that requires a heat press to transfer. UV DTF is for hard, rigid surfaces. It uses UV-curable ink and a pressure-sensitive adhesive, requiring no heat or powder. The consumables and equipment are completely different and not interchangeable.

Both use UV-curable inks, but the method differs. Standard UV printing is a direct-to-object process where a flatbed printer prints directly onto the final product. This is excellent for flat or slightly curved items but cannot handle highly irregular shapes or full-wrap designs. UV DTF is a transfer-based process. It prints onto a film first, allowing the design to then be applied to virtually any shape, including those that cannot fit into a direct printer.

This is another textiles vs. hard goods comparison. Direct-to-Garment (DTG) printing applies ink directly onto cotton-based fabrics and requires pre-treatment. UV DTF is designed exclusively for non-fabric items and requires no pre-treatment, making the workflow simpler and more versatile in its material application.

Sublimation uses heat to turn a special dye into a gas, which then permeates the surface of polyester or specially coated materials. Its application is limited to these specific substrates, and it requires a heat press. UV DTF holds a massive advantage in material diversity, as it can be applied to almost any material (glass, metal, wood, plastic) without heat and without requiring a special coating. This significantly lowers the barrier to entry for customizing a wider range of products.

The business case for investing in UV DTF technology is built on four powerful pillars:

Extreme Durability: The UV-cured ink is essentially a layer of hardened plastic, making the prints highly resistant to scratches, abrasion, and moisture. They are waterproof and can withstand handling far better than simple paper stickers or some other printing methods.

Unmatched Material Diversity: This is the technology's standout feature. One printer allows you to decorate glass, ceramics, metals, wood, plastics, leather, and more. This versatility enables businesses to enter multiple markets and cater to a wide array of client needs with a single equipment investment.

Exceptional Print Quality & Efficiency: UV DTF produces photo-realistic images with sharp details and vibrant colors. The ability to print white ink provides an opaque base for vivid graphics on dark or transparent surfaces. The addition of varnish creates premium 3D textured and high-gloss effects. All-in-one systems like the Refinecolor RF-ZZ2F, which combine printing and lamination, offer outstanding efficiency, saving labor, time, and factory floor space.

No Heat Press or Pre-Treatment: The elimination of heat presses and chemical pre-treatments simplifies the workflow, reduces equipment costs, and allows for the decoration of heat-sensitive items, unlocking new product possibilities.

For businesses looking to enter the lucrative UV DTF market, choosing the right equipment is the most critical decision. The ideal entry-level printer should be reliable, easy to operate, and offer a professional, integrated workflow. The Refinecolor RF-ZZ2F Roll to Roll UV DTF Printer is engineered to be precisely that solution. It eliminates the complexities of separate printing and lamination steps by integrating both into a single, seamless, and automated process. Featuring dual Epson XP600 printheads, a robust Hosonsoft N10 mainboard, and an intuitive Riprint software package, it provides a turnkey solution for producing high-quality transfers right out of the box. Its roll-to-roll design is perfect for efficient production runs, making it an excellent investment for both beginners and established businesses aiming to expand their capabilities.

Learn more about the Refinecolor RF-ZZ2F and our partnership opportunities.

The versatility of UV DTF printing translates directly into a vast range of profitable applications.

A UV DTF printer is used to create permanent, high-quality decals for application on hard goods. It serves the promotional products industry, the personalized gift market, industrial labeling, and small-scale custom manufacturing. It's a tool for adding high-value branding and decoration to existing products.

The possibilities are nearly endless. By leveraging UV DTF technology, businesses can create:

Personalized Drinkware: Custom logos, names, and full-wrap designs on mugs, tumblers, thermoses, and glass bottles.

Custom Electronics: Unique designs for phone cases, laptop covers, headphones, and power banks.

Promotional Products: High-quality logos on pens, keychains, USB drives, and lighters.

Home Décor& Signage: Decorative designs on wooden plaques, acrylic signs, metal plates, and photo frames.

Industrial Labeling: Durable, waterproof labels for equipment, tools, and packaging.

Sporting Goods: Customization of helmets, water bottles, and other gear.

Starting a UV DTF printing business is more accessible than many other decoration methods. The primary investment is the printer itself. A system like the Refinecolor RF-ZZ2F is cost-effective because it combines two machines in one, reducing the initial capital outlay and footprint.

The ongoing costs are consumables:

UV Ink: (Cyan, Magenta, Yellow, Black, White, Varnish)

'A' and 'B' Films: The core media for the transfers.

Cleaning Liquid: For routine maintenance to ensure printhead longevity.

The return on investment can be rapid due to the high-value perception of the customized products. A blank $2 mug can be sold for $15-$20 with a custom UV DTF print, offering significant profit margins. To ensure a smooth start, it is vital to partner with a manufacturer that provides comprehensive training, reliable technical support, and readily available consumables.

Ready to build a profitable customization business? Explore a complete UV DTF printing solution here.

UV DTF printing is not just a trend; it is a transformative technology that is redefining the possibilities of product customization. Its unique ability to produce durable, high-quality graphics for an unparalleled range of materials makes it an essential tool for any business in the personalization space. For overseas agents and distributors, this technology represents a significant opportunity to provide clients with an innovative solution that opens up new revenue streams and offers a distinct competitive advantage.

As a dedicated factory of UV DTF printers, we are committed to providing our strategic partners with not just state-of-the-art machinery like the Refinecolor RF-ZZ2F, but also the comprehensive support needed to succeed. We invite you to explore a profitable partnership with us and harness the power of UV DTF technology to grow your business. Contact us today to inquire about our wholesale and distributorship programs.

You need a dedicated UV DTF printer designed to handle 'A' and 'B' films and equipped with a UV LED curing lamp.

While technically possible to convert certain UV flatbed printers, it's a complex process and not recommended. A dedicated, integrated machine like the RF-ZZ2F is far more reliable and efficient.

No. A regular inkjet or laser printer cannot use UV-curable inks and does not have the required UV curing system.

The transfers are highly durable, scratch-resistant, and waterproof. With proper application, they can last for years, often for the lifespan of the product itself.

How long does it take for UV DTF to cure?

The ink cures instantly (in milliseconds) as it passes under the printer's UV lamp. The adhesive on the back typically reaches its maximum bond strength within 24-48 hours after application.

No. UV DTF is designed for hard, non-porous surfaces. For shirts and textiles, you should use regular DTF or DTG printing.

Yes, it is applied like a sticker, but it is far more durable, permanent, and professional. The ink becomes part of a solid, varnish-like layer bonded to the surface, rather than being a simple piece of printed paper or vinyl.

Yes. The high value added to inexpensive blank products creates very high profit margins, leading to a fast return on investment.

Modern printers have features like automatic nozzle cleaning. Routine maintenance is simple and primarily involves cleaning the printhead capping station. Partnering with a reputable factory ensures access to spare parts and professional technical support.

If your goal is to customize a wide variety of hard goods, especially those with irregular shapes, then UV DTF is likely the best and most versatile option available.

Yes, once applied and fully set, they are completely waterproof.

No. This is a major advantage. The entire process is heat-free.

Not at all. "DTF" simply means Direct-to-Film. Both textile DTF and UV DTF are legitimate, powerful technologies for their respective applications.

No. The adhesive is integrated into the 'A' film. The powder shaker system is only used for traditional textile DTF printing.

You need a UV DTF printer, 'A' and 'B' films, UV-curable inks (CMYK+W+V), and RIP software.

Yes, for all practical purposes, they are considered a permanent application. They are designed to not be easily removable.

Refinecolor Printer will meet you at the ISA Expo in the USA

Refinecolor Printer Attending 2025 SAUDI SIGNAGE & LABELLING EXPO

How Does The UV Printer’s Vision Positioning CCD System Work?

Refinecolor and Epson China participated in the CHN GIFT EXPO in Shanghai

UV Printing Future: The Integration of UV Printing And Laser Cutting in One Machine

UV Label Printer Vs UV DTF Printer: Choosing The Best Solution for Your Business