English

T: +86-180-0799-3137

E: info@refinecolor.com

E: info@refinecolor.com

9F, Building 25, Tian 'an Shenchuanggu, Fenggang Town, Dongguan 523703, China

Views: 0 Author: Site Editor Publish Time: 2025-11-06 Origin: Site

After working with 1,200+ signage shops, advertising agencies, and customization factories, we've noticed a consistent trend: when professionals need to create ADA compliant braille signage, their first search is almost always for a "braille printer." This search quickly branches into two distinct technologies—traditional paper embossers and modern digital UV printers—that couldn't be more different in how they serve the commercial signage market.

Both produce tactile text, but their substrate compatibility, durability, and ability to drive business growth are miles apart. As a solutions provider deeply embedded in the print industry, we've seen firsthand how the wrong tool can slow production, limit client projects, or even lead to non-compliant signs. This guide breaks down the legacy technology that works for paper—and introduces the UV flatbed printer for tactile signs that's becoming the gold standard for businesses looking to meet demand while boosting profits.

For decades, "braille printer" has been interchangeable with "braille embosser." This technology operates like a dot-matrix printer, but instead of ink, it uses mechanical pins to punch raised dots into paper or ultra-thin plastics.

This method is tried-and-true for paper-based braille—think educational books, bank statements, or pamphlets. It excels at its original purpose: affordable, high-volume paper braille.

But for commercial sign-making, its limitations become dealbreakers—especially for clients needing durable, compliant signage:

Substrate Restriction: Embossers can't handle the acrylic, aluminum, wood, PVC, or Sintra boards that define professional signage. They're limited to paper and fragile thin plastics, ruling out most architectural or public-space projects.

Durability Risks: Punched paper dots flatten easily. In high-traffic areas, moisture, cleaning, or accidental contact can wear them down—rendering the sign non-compliant and forcing costly reprints.

Inefficient Workflow: Visual graphics and braille are separate steps. You first print the design, then align and emboss the braille—wasting time on setup, risking misalignment, and creating a disjointed, unprofessional look.

Traditional braille embossers are essential for paper documents, but they're simply not built for the rigor of modern ADA compliant braille signage demands.

Clients today don't want a clunky, separate braille plaque. They want seamless, branded signs that blend visual design with tactile compliance—signs that fit into retail spaces, offices, or public buildings without looking like an afterthought.

This demand has pushed the industry past basic embossing. Some businesses tried braille 3D printers, but they're slow, material-specific, and struggle to produce consistent dot heights (a key ADA requirement). The solution that's stuck? Digital UV printing—fast, versatile, and built for commercial sign production.

Imagine printing full-color graphics and precise braille dots in a single pass, on nearly any rigid substrate. That's the power of a UV flatbed printer for braille plaques—no separate embossing, no alignment headaches, just durable, compliant signs that look intentional.

This process doesn't "emboss"—it builds braille dots using a precision "varnish overlay" technique:

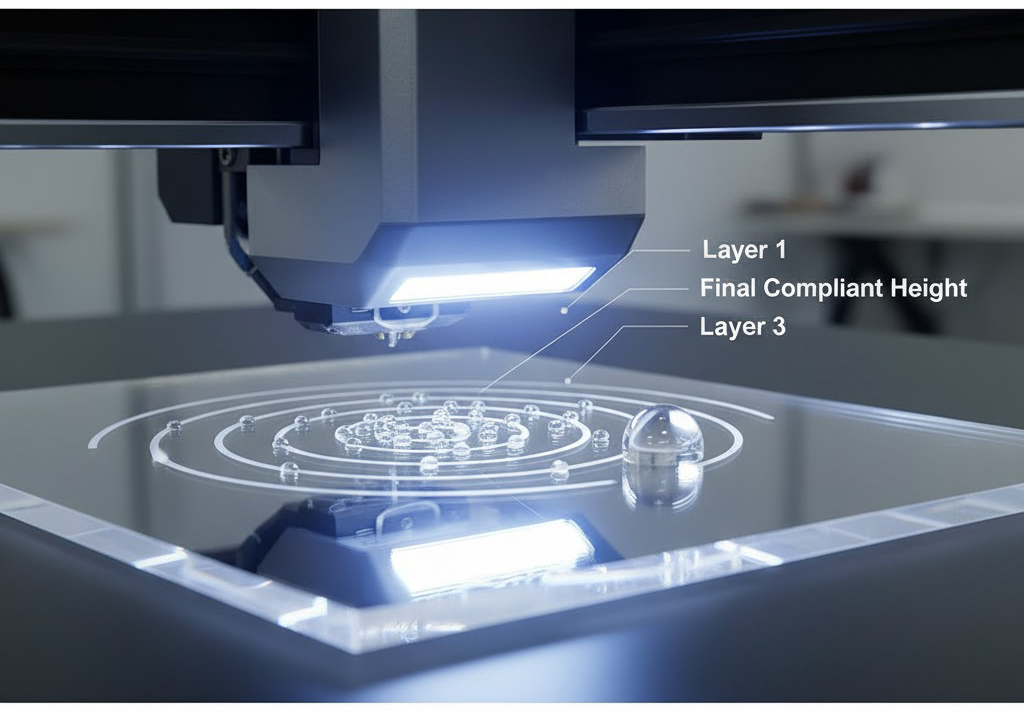

1. The UV printer deposits a tiny, exact droplet of clear UV varnish (or specialized tactile ink) where each braille dot needs to be.

2. A UV-LED lamp directly behind the printhead instantly cures (hardens) the droplet, locking it to the substrate.

3. The printhead repeats this process, layering and curing varnish until the dot reaches the ADA-required height (between 0.059 and 0.063 inches).

4. The result is a hemispherical dot—chemically bonded to the substrate—that's scratch-resistant, moisture-proof, and built to last in high-traffic environments.

This is UV printer braille—a digital, integrated solution that's redefining how businesses meet ADA compliance.

For signage businesses, investing in a UV printing machine for braille plaques isn't just about checking a compliance box. It's about unlocking new revenue streams and serving clients who need more than basic signs.

This is the biggest game-changer. A UV flatbed printer works with nearly any material clients request for ADA compliant braille signage:

Acrylic (clear or colored)

Metals (aluminum, brass, stainless steel)

Wood (natural or stained)

PVC, Sintra, and foam boards

Glass (for specialty interior signs)

Rowmark and other sign-specific substrates

You can take on projects you'd have to turn down with an embosser—from retail store signs to office wayfinding to public building plaques.

UV-cured varnish dots are made of hardened acrylic polymer—far more durable than punched paper. They resist wear, moisture, and cleaning chemicals, ensuring the sign stays compliant for years.

And because braille and graphics are printed in the same pass, you eliminate alignment errors and cut production time in half. No more matching embossed braille to printed designs—just perfect, compliant signs every time.

With UV printing, braille becomes part of the design, not an add-on. You can print vibrant logos, textured backgrounds, or brand colors alongside precise braille dots—creating signs that clients are willing to pay a premium for.

This shifts your business from "sign maker" to "architectural design partner." Clients don't just get a compliant sign—they get a piece that enhances their space.

ADA compliance requires consistent dot height, spacing, and shape—something AI-generated guides often gloss over, but real-world clients demand. UV flatbed printers use high-resolution printheads (like Epson's industry-leading models, highlighted in TexIntel's print technology reports) and advanced RIP software to ensure every dot meets ADA specs.

We've seen clients win government and corporate contracts specifically because their UV-printed braille is more consistent than 3D-printed or embossed alternatives.

If you started searching for a "braille printer," you're really looking for a tool that can handle commercial signage demands. A UV flatbed printer isn't just a replacement—it's an upgrade that opens new opportunities.

Our lineup is built for the real needs of signage businesses:

For custom work and small-format signs: The Refinecolor A3+ UV Flatbed Printer is compact but powerful. It's perfect for customization factories or creative studios testing the ADA compliant braille signage market, or handling small-batch orders like nameplates or restroom signs.

For production-level sign making: The Refinecolor 6090 UV Flatbed Printer is a workhorse. Its larger bed size handles multiple signs or large architectural plaques efficiently, making it ideal for advertising agencies and sign shops with high-volume demand.

To explore how UV printing can transform your braille signage offerings—from compliance to profitability—we invite you to learn more about our full range of UV Flatbed Printers.